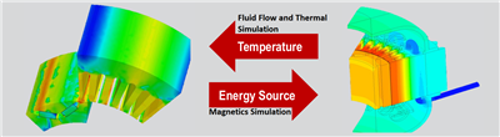

Webinar Description |

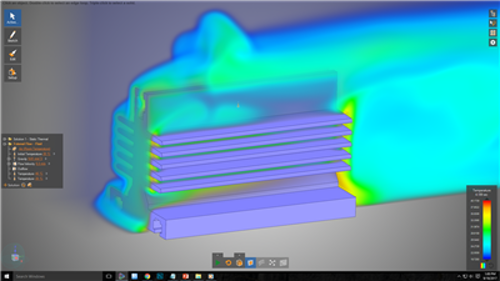

Modeling of a Shell and Tube Heat Exchanger

This webinar examines simulating the fluid, thermal and structural physics of modeling a shell and tube heat exchanger with Ansys Discovery AIM. In addition, the webinar will cover CAD import, setting up boundary conditions, solving and analyzing the results.

Recent CFD Projects in Fluid-Structure Interaction (FSI)

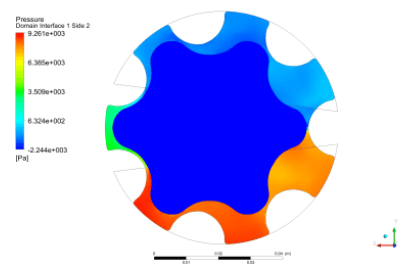

High-Pressure Pump

Investigated the fluid failure mechanism and redesign of a high-pressure reciprocating pump used to inject water into the reservoir in the fracking process. The model captured the transient multiphase flow as the pump piston and valve rigidly moved.

Ball Gate Valve

Performed a root cause analysis of the Ball gate valve, which was having vibration lifecycle problems. The analysis of the structural motion reacting to the turbulent fluid identified the problem, and with a small change to the design, fixed the lifecycle problems.

FSI of Blood Flow around a Vein Valve

For a new medical device that is now in the prototype stage, a biotechnology company recently asked for a computational fluid-structure interaction (FSI) analysis for a healthy patient-specific pulmonary arterial tree utilizing the unified continuum and variational multiscale (VMS) formulation.

Reciprocating Engine

Calculated the spatial and time-varying solid body temperature using conjugate heat transfer model in a transient, compressible fluid system. The fluid model was used with a corresponding structural model to identify areas of high stress due to thermal loading.

Reciprocating Compressor

Modeled the transient effects within a reciprocating compressor with compressible methane gas utilizing Ansys Fluent’s moving mesh capabilities.

Industrial Duct

Analyzed the turbulent vortex shedding and the potential fluid-structural interaction caused by the fluid vortices that could be shed of the internal duct structure.

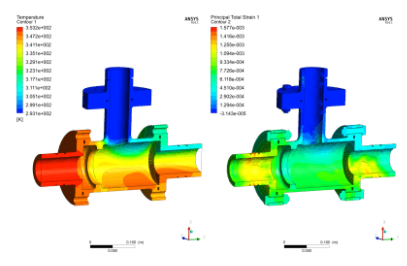

Case Study: Impact of Flows on Globe Valve Thermal Shock Clearances

Valve performance in a nuclear power plant needs to be proven under difficult operating conditions. One certification test that passed this empirical testing was the 225°C thermal shock test.

A large globe valve with a nominal diameter of 150 mm is used in this investigation to explore such shocks both numerically and empirically.

Ansys Maxwell‘s automated testing loop is the internal software site of the experimental campaign.

Ten thermal shocks are administered sequentially in pressured cold and hot water. The 40 thermocouples fitted uniformly along the height of the tested valve.

The ten studs that make up the body-bonnet flange are fitted with strain gauges, enabling the tracking of changes in the clamping forces inside the flange. A 3D numerical simulation of such a shock in the valve is conducted.

It is done using a variety of multiphysics simulations, including fluid, heat conduction, and mechanics. The mechanical simulation represents nearly 50 separate parts with various contacts. This simulation is provided in two distinct iterations for Fluid-Structure Interaction (FSI) Consulting services, the second of which takes into account a heat transfer that happens in clearances.

When it comes to the temperature in the studs, there is a high correlation between modeling and experiment. Only the second simulation is able to accurately capture the tightening changes seen experimentally at the start of cold and hot shocks in terms of clamping forces.

For more information on this case study, contact our engineering experts HERE.