Introduction to Forensic Engineering Simulation

When an asset fails, the ensuing investigation will surface a slew of facts, from which organizations need to design an actionable path forward. From fracture locations, load histories, temperature excursions, to test results, what the investigation turns up will close the loop from cause to prevention. This is where simulation-driven forensics shines. The same models used to reconstruct an event can be extended to validate fixes, set new limits, and harden procedures so the problem does not continue.

Below is a practical framework SimuTech Group uses to translate failure investigations into safer products and policies, grounded in physics, traceable to the evidence, and ready for auditors, regulators, and courts alike.

How To Break A Cycle of Repeated Failures

Many organizations perform root-cause analyses, yet continue to see similar failures again and again. Common reasons include:

- Findings stop at symptoms. The initiating mechanism is identified, but system interactions (controls, human factors, environment) are not addressed.

- Corrective actions aren’t validated. A design tweak is implemented without verifying performance across the full operating envelope.

- Policies lag the physics. Limits, procedures, and training do not reflect what the loads and materials truly allow.

- Documentation gaps. Assumptions, margins, and responsibilities are not captured in a way that survives personnel and vendor changes.

A forensics-to-prevention workflow solves these by pairing evidence with simulation and then binding both to requirements, procedures, and monitoring.

Forensic Engineering Simulation: a Closed-loop Workflow

- Preserve and quantify

Secure parts, metadata, and site measurements. Convert field evidence into usable inputs: geometry, boundary conditions, load spectra, temperature profiles, materials data (including heat treatments and manufacturing variability). - Reconstruct with high-fidelity models

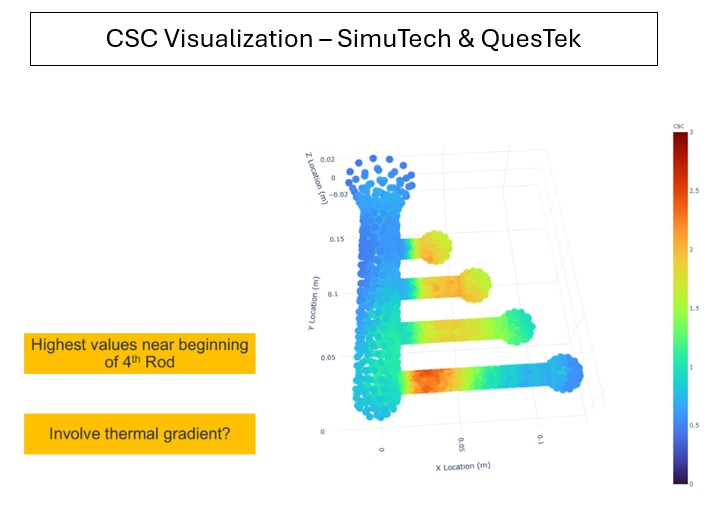

Use FEA for stress, strain, fatigue, and fracture; CFD for thermal and fluid loads; multibody dynamics for impact and motion. Calibrate models to test data and failure morphology so the digital reconstruction reproduces the real event with traceable margins. - Separate root cause from contributing factors

Run sensitivity studies and what-ifs: what fraction of risk came from an undersized fillet vs. out-of-spec torque vs. an unexpected thermal gradient? Quantifying contributions focuses resources where they matter. - Translate physics into requirements

Convert insights into specific, measurable constraints: minimum radii, allowable stress ranges, maximum dwell time at temperature, vibration limits, installation torque windows, and inspection intervals. This is the bridge from “what happened” to “what must never happen again.” - Design out the hazard

Apply topology changes, new alloys, coatings, fillets, ribs, or damping features. Validate alternatives virtually across the full duty cycle and off-nominal conditions. If operations contribute significantly, redesign the process or controls, not just the part. - Verify fixes with test-ready evidence

Create a Verification & Validation plan that ties simulations to instrumented tests (strain gauges, thermocouples, flow meters). Use mesh-independence checks, uncertainty quantification, and acceptance criteria that match the updated requirements. - Institutionalize through policies and training

Update SOPs, work instructions, torque charts, alarm setpoints, inspection methods, and spare-parts specs. Build short, visual training that explains not only what to do but why the limit exists, anchored to the physics. - Monitor, learn, and adjust

Implement condition monitoring or lightweight digital twins to watch key indicators (temperature rise, vibration, pressure pulsation). Trigger corrective action when trends approach the new limits; feed learnings back into the model.

Build a Safety Case that Stands Up To Scrutiny Through Forensic Engineering Simulation

Regulators, customers, and courts all ask the same questions: What failed? Why? How will you prevent a recurrence? A safety case anchored in forensic engineering simulation answers these question with clarity:

- Traceability: each requirement links to evidence (photos, measurements, model results, tests).

- Rigor: models include mesh and time-step studies, material variability, and uncertainty bounds.

- Relevance: scenarios span the true operating envelope, not just nominal conditions.

- Repeatability: procedures document how to rerun the analysis and reproduce the decision.

This documentation becomes the backbone of CAPA (Corrective and Preventive Action), Management of Change, and internal audits.

How SimuTech Group Can help

- Evidence-based modeling: FEA, CFD, thermal, and dynamics calibrated to the actual failure.

- Option screening: rapid parametric studies to rank design and process changes by risk reduction per dollar.

- Test correlation: instrumentation plans and on-site support to verify that the fix performs as modeled.

- Policy integration: converting technical limits into clear SOPs, torque specs, inspection steps, and training assets.

- Monitoring setup: practical sensor strategies and lightweight digital twins to keep improvements on track.

Our objective is straightforward: make the next incident statistically unlikely, and prove it with data you trust.

Close the Loop with Forensic Engineering Simulation

A thorough investigation tells you what happened. A prevention program tells you what changes and who owns it, while confirming the result with physics and numbers. When simulation, test, and operations move in lockstep, organizations strengthen the entire system.

If you’re ready to turn a recent failure (or a near miss) into lasting improvements through forensic engineering simulation, SimuTech Group can help you move from findings to safeguards. Contact us today for assistance.