Multiphase Flow Consulting

Multiphase flow simulation reveals the complex interactions between gases, liquids, and solids, helping engineers predict real-world behavior in systems where multiple phases coexist, mix, or transform.

Multiphase flow simulation reveals the complex interactions between gases, liquids, and solids, helping engineers predict real-world behavior in systems where multiple phases coexist, mix, or transform.

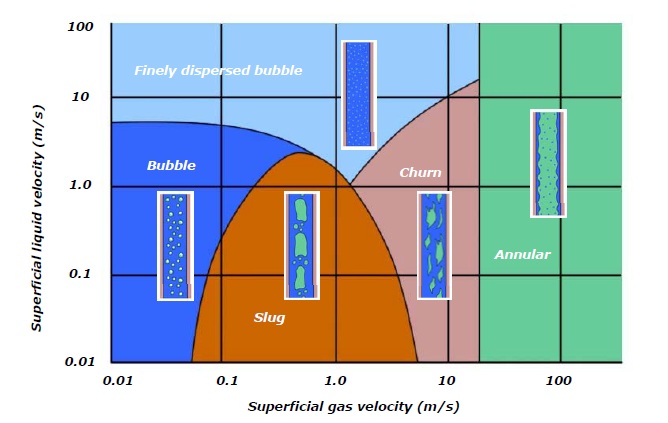

Multiphase flow simulations are used to model the flow of two or more different phases. Phases refer to whether the material flowing is a gas, liquid, or solid. These different phase materials can be mixed, such as air bubbles in a mixing tank, or separated, such as water flowing over a spillway.

A phase is described as continuous if it fills the space in which it is located, like air in a chamber or water in a tank. By comparison, a dispersed phase involves particles that are distributed within a continuous phase. For example, droplets of oil in a spray, sand particles in water, or gas bubbles in a mixing tank are three different types of dispersed phases.

Phase changes, such as liquid to gas during cavitation or solid to liquid during melting, can also be simulated using Ansys CFD software.

Ansys CFD software offers a wide range of models for simulating multiphase flows. At SimuTech, we have engineers experienced in multiphase modeling who can help you simulate your conditions or processes involving the flow of multiple phases. Several examples of our recent multiphase flow modeling projects are described below.

Whether it’s optimizing separator inlet piping or analyzing the Basis of Design, such as enhanced separator configurations and internal components, SimuTech Group performs specialized Multiphase Flow studies to support fast, informed decision-making and enhance the scope of your flow assurance efforts.

Knowledge sharing is a core component of SimuTech Group’s consulting approach. Our expertise — spanning topics such as Multiphase Flow and Applications, Flow Conditioning, Flow Assurance, Compact/Cyclonic Separation, and more — is fully available to clients through dedicated training at the “Modeling and Applications” level.

On-site consulting is available, along with technical software training (delivered either on-site or remotely) for the modeling tools that support real-world field applications. These services help bridge the technology gap between academic models and the practical tools needed in the field.

Calculated the cooling, corrosion, and erosion effects of water spray using particle tracking and phase change models to capture the complex multiphase interactions on the internal surfaces of the quench tower.

Calculated the resulting turbulent fluid motion resulting from the mixing of black oil/natural gas and water in unusual operating conditions for undersea pipelines.

Predicted pressure drops and erosion in “Steam Assisted Gravity Drainage” bitumen recovery systems, requiring modeling the multiphase bitumen-water emulsion flow through various flow control devices at downhole conditions, including the flashing effect for the SAGD extraction process.

Modeled the spray injector to predict the cavitation location and rate, evaluating the implications on the resulting spray during the cyclic transient injection of a diesel injector.

Calculates the flow rate across a choke valve at various pressures, corresponding gas oil ratios (GOR), and valve positions.

SimuTech Group’s CFD consulting team has deep experience modeling multiphase flow scenarios involving gas, liquid, and solid interactions. From separated flows and mixing tanks to flow assurance and phase transitions, our engineers use Ansys CFD tools to deliver accurate, actionable insights for even the most complex systems. Whether you’re developing new equipment or refining existing designs, multiphase simulations can reveal critical flow behaviors that are difficult to capture through testing alone.

Contact us today to learn how simulation can help you solve your toughest multiphase flow challenges!

Our team of experienced engineers can assist you at any step of your process.