A design solution for a solenoid coil’s control system is presented in this engineering EDUblog. The electrical component of the solenoid is used in conjunction with a traditional proportional, integral, and derivative (PID) controller unit in this control model to examine the effectiveness of the control system.

The solenoid has been used as an electrodynamic device for numerous electrical and mechanical components in recent years. (Often in tandem with Actuators). Replicating the impact of electricity upon motion, it acts like a magnet.

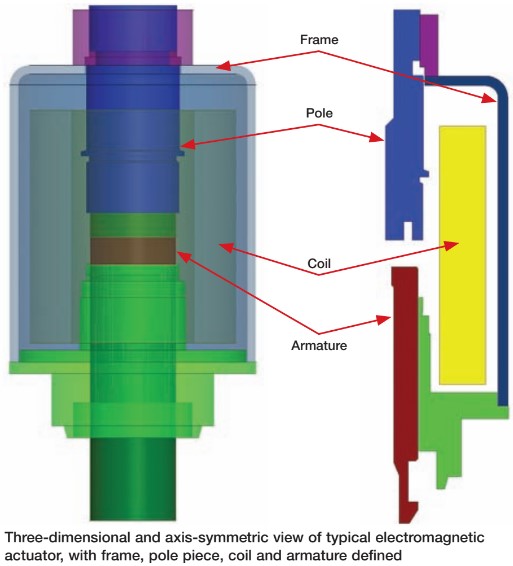

So a coil carrying a current coiled to the right size and form to enclose an iron core known as a plunger or armature, which provides rectilinear motion, can be thought of as a solenoid.

Solenoids are utilized as actuator devices and employed as a control element for speedy and safe execution of switching jobs inside fluid in a variety of applications, such as fluid systems. They also offer low electrical power consumption and compact controller design.

In addition to the associated mechanical circuits, solenoids can be theoretically modeled as electromagnetic circuits for use in control systems. One or more electrical inputs are used to infer the interactions between the currents in coil conductors and the corresponding magnetic fields.

The mechanical subsystem of the solenoid is represented as a mass model with a single conservative node, whereas the electrical component of the solenoid coil can be represented as a series combination of resistor and inductor elements. Many academics have investigated the solenoid valve’s dynamic response properties through theoretical and experimental studies.

In other cases, in order to simulate solenoid valves with changing properties, researchers have used analysis methods to transform physical solenoid models into equivalent mathematical models. In an effort to confirm that the solenoid valve operates in accordance with predetermined design guidelines, various research studies have also examined the solenoid’s magnetic properties.

It should be mentioned that the solenoid valve has been used as a control element in electromechanical circuits in several real-world applications to fulfill the demands of motion control operations.

In this study, the solenoid coil was modelled and simulated based on solenoid parameters, with an emphasis on the electrical component of the solenoid, to create a closed loop control system and test the system’s responsiveness to the step input signal.

The solenoid coil’s resistance and inductance values were assumed to match the laboratory measurements of these components. The solenoid control system employed a PID controller model as a compensator, and the overall response of the control system was determined by tuning the gain factors of the controller unit using the ANSYS software program.

Thus, the ANSYS software configurations and subsequent design and testing parameters serve as the foundation for this article’s organization.

Indeed, a common misconception in the field of automation and robotics is that instantaneous results and financial returns are to be enjoyed by the companies adopting such technologies. This was true both in the 1980’s as it is today in the 2020’s.

In fact, there are several examples where automation attempts failed did not lead to the anticipated improvements in business operations and overall ROI. In the late 1980s, General Motors Corporation made an unsuccessful attempt at doing that. IBM made an effort to fully automate the printer manufacture, however the efforts were unsuccessful. The key takeaway is that technology is only useful when properly applied.

The productivity of classic manufacturing processes, such the manufacture of steel and coal, has increased significantly as a result of process automation. On the other side, factory automation facilitated the development of novel tools, methods, and techniques, as seen in the cases of materials engineering for nanofabrication and solid state electronics.

But as history has demonstrated, early optimism and hopes that all facets of the production process, starting with a design and the isolated automated manufacturing cells, could be united into one coherent integrated system, frequently fell short of expectations. There are instances of businesses that invested a significant amount of time, money, and resources in automation yet failed to successfully integrate it into reliable, functional systems.

The productivity of classic manufacturing processes, such the manufacture of steel and coal, has increased significantly as a result of process automation. On the other side, factory automation facilitated the development of novel tools, methods, and techniques, as seen in the cases of materials engineering for nanofabrication and solid state electronics. Sophisticated modeling of a controlled solenoid has aided much to development.

But as history has demonstrated, early optimism and hopes that all facets of the production process, starting with a design and the isolated automated manufacturing cells, could be united into one coherent integrated system, frequently fell short of expectations. There are instances of businesses that invested a significant amount of time, money, and resources in automation yet failed to successfully integrate it into reliable, functional systems.

The creation of semiconductor devices, nanofabrication, non-contact technologies for material surface processing, and fast prototyping are just a few of the high-tech projects that several local enterprises are working on in the field of materials science and engineering.

Here, the production procedures are mostly based on job shop and cell activities, with very little assembly line work.

In order to monitor and manage the fabrication processes, which include lithography, film deposition and growth, annealing and diffusion, metrology, etching, baking, and curing, clean room technologies and materials engineering require integrated computer-based automated equipment.

A high-tech Pittsburgh company called Advantech US creates technology for the production of thin film electrical microcircuits. Vacuum deposition equipment is used in the operations to create prototype thin-film circuits and create microcircuit patterns using photolithography.

Plextronics Inc. (acquired by Solvay in 2014), another Pittsburgh-based business engaged in materials engineering, develops and produces conductive polymers used for printed electronics, which includes next-generation products for light, power, and circuitry, such as flexible displays, plastic solar cells, and organic RFID tags.

Extrude Hone, a division of Kennametal, provides cutting-edge material solutions based on automated, non-contact material processing. The facility uses abrasive flow machining (AFM), micro-flow machining (AMF), thermal energy machining (TEM), and electrolytic machining as technological methods (ECM).

Powerex, Inc., a manufacturer of high power solid state devices, is another example of a company that makes semiconductors.

The technologies utilized there include clean room technologies, automated production based on cell manufacturing with materials engineering connected to diffusion processes, and software design tools.

For the automotive, alternative energy, aerospace, medical equipment, electrical equipment, communication, and other industrial domains, the firm is a leading supplier of discrete, modular, and integrated high power semiconductor devices and solutions. IGBT assemblies, thyristors & diode modules, MOSFET modules, etc. are a few examples of the items.