Failure Analysis Consulting

Failure investigation requires a comprehensive understanding of the nature of materials, environment, and operating loads to aid in identifying the root cause of a failure.

Failure investigation requires a comprehensive understanding of the nature of materials, environment, and operating loads to aid in identifying the root cause of a failure.

There are often several contributing factors that combine to produce such a failure.

As a result, selecting an engineering consultant that can property diagnose a failure, and determine the appropriate testing techniques to determine root cause, is critical.

Not only for correcting the current liability, but also to ensure adequate preventative measures are applied to current and ongoing projects or apparatuses.

In some cases, two structural components that are perfectly acceptable separately can fail when placed near one another.

For example, an interaction between the operating equipment and the supporting structure might create a destructive resonant operating condition resulting in equipment failure.

Frequently, the steady and cyclic load components are not known. For these cases, failure investigation offers an excellent opportunity to define the actual magnitude and frequency of the operating loads.

Failure analysis requires a broad and comprehensive understanding of the many different failure modes that exist for any given system.

Frequently, two or more modes contribute to a component failure or system-level failure.

SimuTech Group has extensive, first-hand experience in failure analysis for industrial and commercial equipment, turbomachinery, and structural components for a wide range of applications.

Common requests from business partners (including, but not limited to):

Fatigue is probably the most common mode of failure. It is generally understood to be the gradual deterioration of a material when subjected to repeated loads. Key factors are the mean stress (average of maximum and minimum), and the variation (difference between the maximum and minimum) components.

While most data have been developed for the fully reversing application, there are techniques for applying these data to alternate fatigue situations. Sometimes the stresses vary due to normal operation, and for other cases there is an excitation of a harmonic frequency which acts to amplify the applied load.

SimuTech Group has extensive experience with analyzing applications with variable loads and defining the associated application criteria. Fatigue evaluative mechanics often include stress-life, strain-life, and fracture mechanics.

The dynamics of equipment can be a major factor in design life. Consideration of natural frequencies and modes of excitation can have a major impact on localized stress. Excitation of a part at or near its natural frequency can produce an amplification of stresses.

A complete system will usually have many modes. These must be defined, and all the forcing functions analyzed to avoid interaction.

SimuTech Group has the capability to do 3D FEA models to define vibration modes and frequencies of housings, rotating shafts, and complex structures.

For existing equipment, SimuTech Group can offer testing services to measure vibration frequencies, modes, etc. FEA and testing services are complementary tools for precision analysis of complex structures.

For some applications, corrosion and fatigue can act in a synergistic fashion. Corrosion generates local damage in the form of pits. The growth of the pits is a complex electro-chemical reaction.

The rate of corrosion is dependent on the metal type, corrodent concentration, temperature, and the availability of oxygen. When these pits grow at a location with high stress, the pit can be the nucleation point for the initiation of a fatigue crack.

SimuTech Group has specialized corrosion fatigue testing facilities which permit tests to be performed in sour (H2S), sweet (CO2) and other corrosive environments. Rapid corrosion fatigue testing for businesses with tight deadlines is also available. Founded on the RSL method, quantitative evaluations of corrosion fatigue susceptibility can be generated on-demand.

Thermal fatigue, also known as thermomechanical fatigue, is a degradation mode involving simultaneous instances of each thermal and mechanical strain. Significant excursions of temperature can also create stress. The range of temperatures and the rate of change during heat-up and cool-down have a major impact on the associated stress.

SimuTech Group has analyzed engine components where thermally induced stresses were the controlling factor for early fatigue failure.

Crack initiation is related to the stress-strain hysteresis loop. The area within this loop is the dissipated energy that promotes crack initiation and propagation.

Each cycle represents an infinitesimally small amount of energy, but when this process is repeated, the total energy can be quite significant.

SimuTech Group has done extensive analysis of the crack initiation phase of fatigue failure in the United States and Canada, as well as internationally.

The material properties, the stress range, and the crack size govern the crack propagation rate for a part. A key factor that can affect the crack growth rate is the environmental chemistry at the crack tip.

The combined action of corrosion and fatigue does substantially increase the crack growth rate. Other factors that can affect growth rate include the temperature and structural resonance. The technology of fracture mechanics, crack infiltration, and growth is well understood at SimuTech Group.

SimuTech Group has recently developed an advanced “state-of-art” fatigue life prediction computer code called LifeCycle. This software is based on proven NASA technology.

SimuTech Group has used this program to predict the remaining life of turbine blades and for failure analysis under known operating conditions. This proprietary code has been developed to solve fatigue problems involving components subject to complex load sequencing.

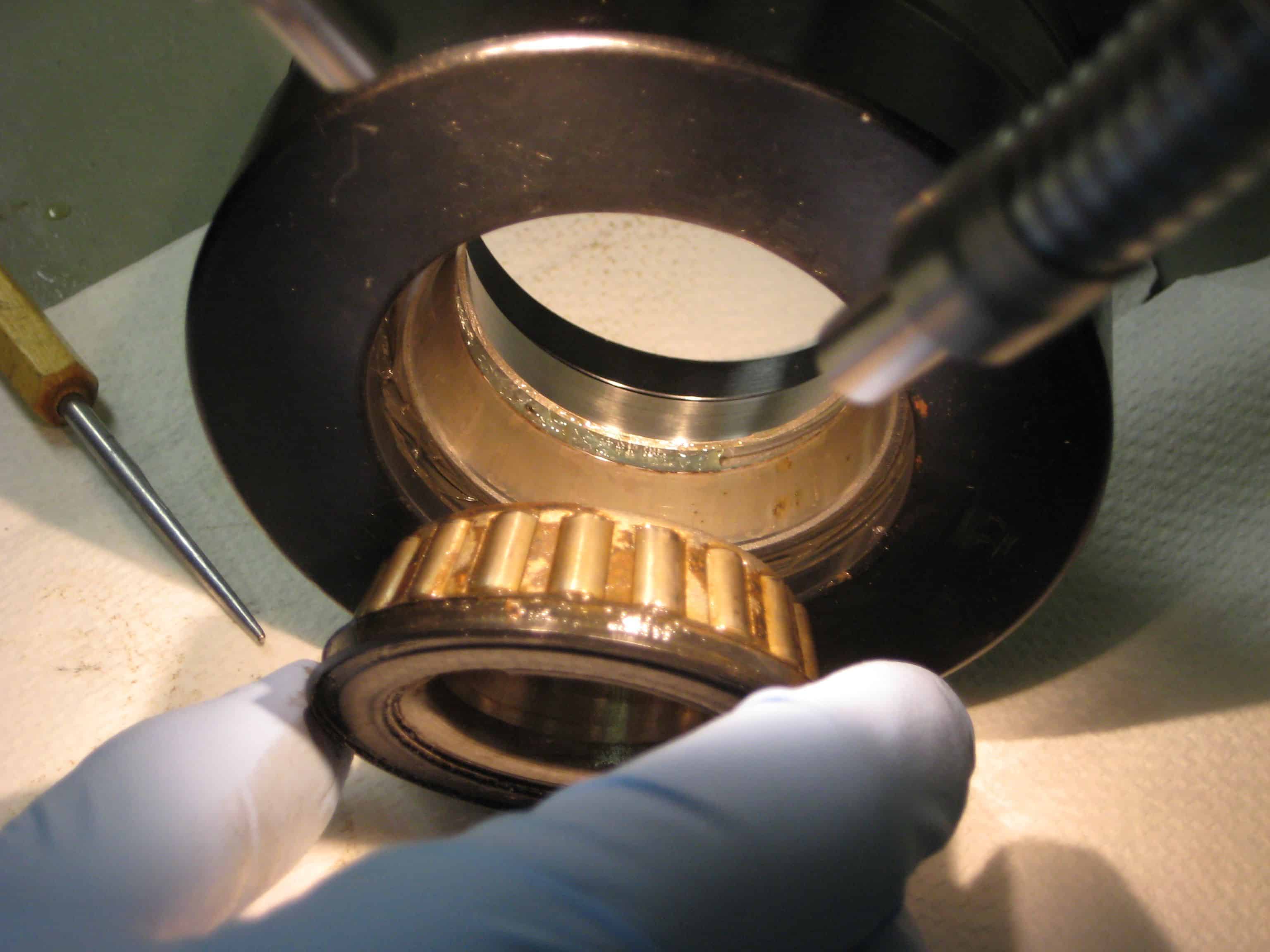

Spalling and pitting (gears and bearings) are surface fatigue phenomena. The failure occurs when high contact stresses produce sub-surface tensile and shear (Hertzian) stresses that exceed the material fatigue limits.

Gears and bearings are often subjected to large contact stresses. While the result is easily observed, the underlying cause can be a challenge. SimuTech Group has found that understanding complex dynamic interaction, such as resonance and environmental factors, is often important to solving these types of problems.

Fretting damage occurs on the mating surfaces of components subject to normal pressure and tangential oscillatory motion. The surface damage can take the form of wear, or for high normal forces, fatigue. The process can be accelerated in the presence of chemical attack.

Additionally, under mechanical loading, such as static tensile or fatigue stress and wear/fretting, the surface of metallic materials is deformed and the passive film is locally and repetitively broken, which can lead to rapid corrosion due to full environmental exposure.