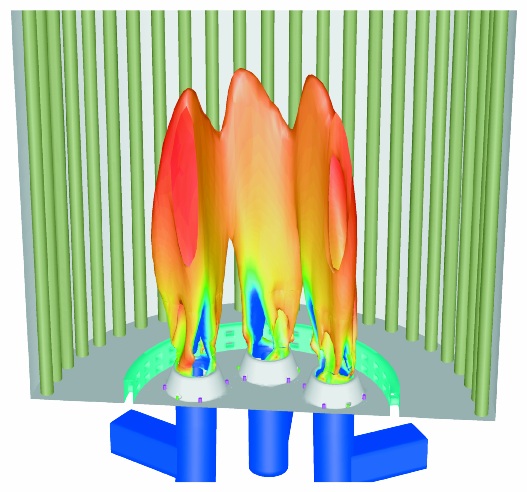

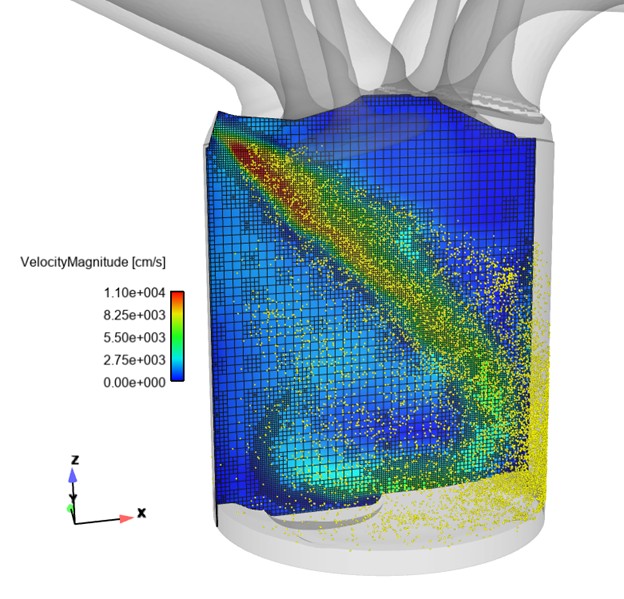

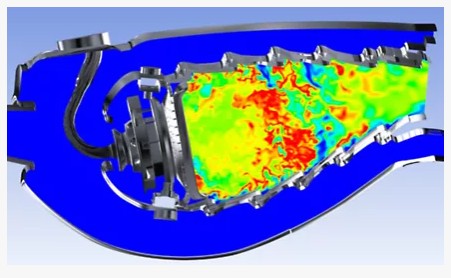

Reacting Flow and Combustion Analysis

Reacting flow computational fluid dynamics (CFD) is a specialized area within fluid dynamics that focuses on the simulation of flows including chemical reactions. This involves the combined simulation of fluid flow, heat transfer, and chemical reactions. Some types of reacting flows are Combustion, Catalysis Reactions, Electrochemical Reactions, and Chemical Vapor Deposition (CVD).

Reacting flows often involve numerous species and reactions, requiring detailed chemical kinetics, or reaction rate, models. Accurately capturing the interaction between turbulent flow structures and chemical reactions is challenging but important for accurately modeling reacting flows.