Structural Dynamics Simulation Consulting

Enabling engineers to account for and analyze time-dependent, structural dynamics characteristics at the design level.

Enabling engineers to account for and analyze time-dependent, structural dynamics characteristics at the design level.

Structural systems can vibrate or oscillate due to their mass and stiffness. When structural systems are subjected to loads that vary with time or frequency, the dynamics of structural vibration is typically analyzed. The primary reason vibration is studied is to design assemblies that can resist vibration fatigue failure. The second reason is to isolate or minimize the transmission of vibration from the vibrating source.

Structural dynamics begins with the study of free vibration, often referred to as modal analysis. Free vibrations are how a structure oscillates when an external load has been removed. Using modal analysis, the basic vibration characteristics, often referred to as natural or resonant frequencies and vibration mode shapes of the structure are first determined.

When the structure is subjected to sustained periodic loading, using the harmonic analysis tool, one can predict the steady dynamic behavior of the structure, enabling one to verify whether their structural designs can successfully overcome resonance and other harmful effects of such periodic vibrations.

Spectrum or frequency analysis is used to determine the spectral vibration responses of structures subjected to random or frequency-dependent loading conditions such as earthquakes, wind loads, ocean wave loads, rocket motor vibrations, etc. When time-varying loads require evaluation of a structure’s dynamic vibration response, a transient vibration analysis is conducted.

A large pole-mounted electronic switch was validated for structural dynamics integrity due to response from an earthquake event.

The dynamic response of a mash feeder tube was investigated with regards to system excitation.

Structural dynamics simulation of MIL Standard triangular wave shock and random vibration requirements.

Comparative fatigue investigation into truck cab step brackets subject to MIL-STD-810G random vibration.

Resolving cavity resonance problem by applying finite element analysis (FEA) computational methods to rotordynamics.

Reconstructing model-to-model crash or collision scenarios by employing explicit dynamics simulations available in ANSYS LS-Dyna.

Dynamic analysis and comprehensive seismic evaluation.

Seismic stability and gate operability.

Hydrodynamic analysis.

Analysis for tornado generated missile impact.

Random vibration evaluation for flight operation.

Modal and acceleration investigation due to improper constraint.

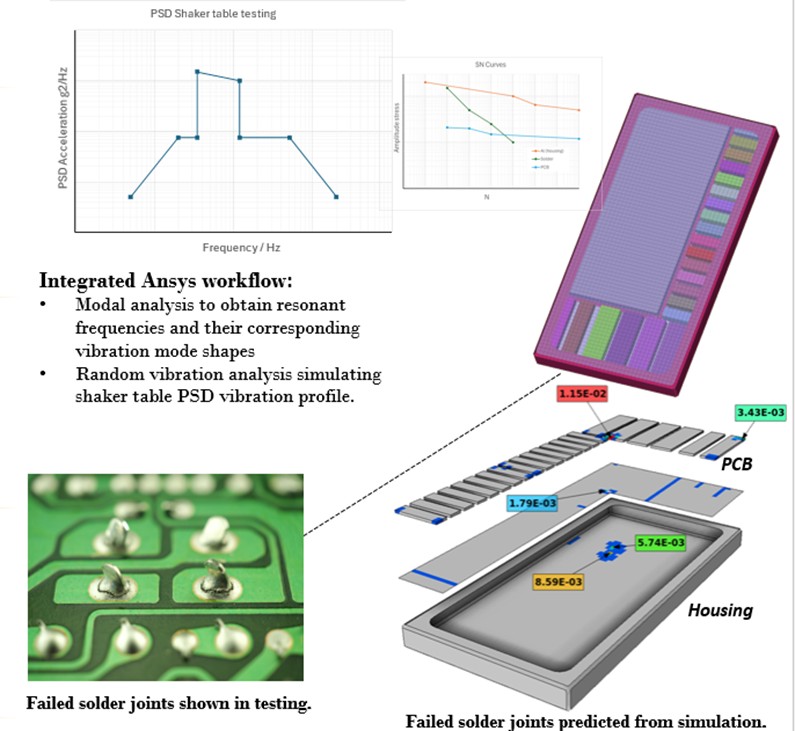

Performing shaker-table tests with a PSD (random) vibration specification is a common practice in real-life vibration testing environments. Here is an application of simulating shaker table testing for an electronic device:

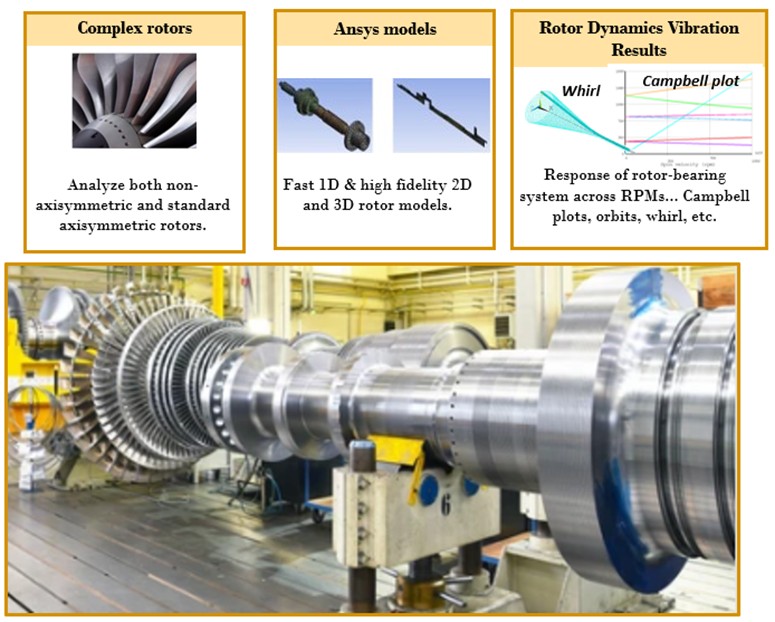

The vibration dynamics of complex rotor configurations can be simulated.

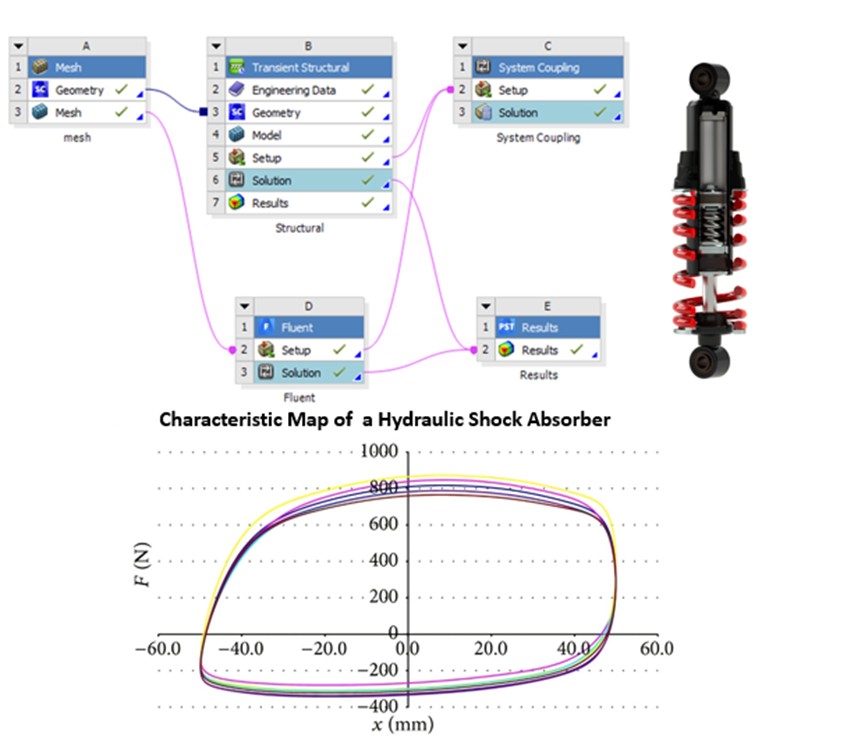

Predicting the vibration behavior of a hydraulic shock absorber is achievable through a bi-directional simulation of fluid structure interaction.

The correlation of Ansys simulation models with testing can be done using Ansys’ NVH Toolkit.

An illustration showing the Modal Assurance Criterion (MAC).

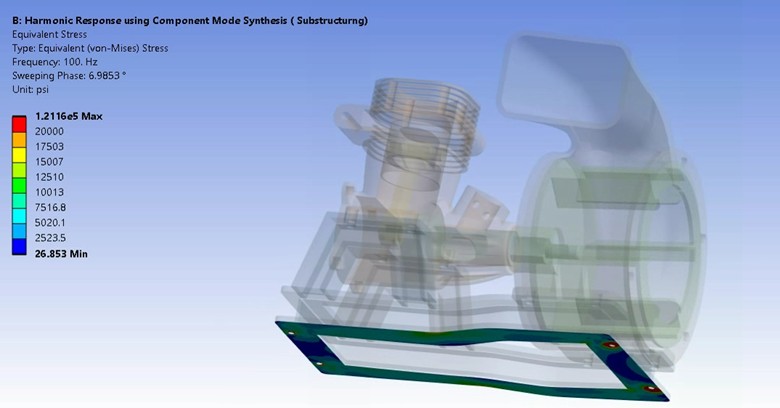

To handle harmonic response, random vibration and spectrum response of large assemblies, superelements can be implemented by Component Mode Synthesis (CMS).

Allow a skilled SimuTech Group engineer help you to reduce the need for physical vibration testing and shorten development and validation time. With our 40+ years of experience and numerous successful vibration projects under our belt, we can assist you in resolving your vibration issues and moving your designs forward.

Our team of experienced engineers can assist you at any step of your process.