Connecting the component parts of a system to make sure they work as expected and designed can be an engineering challenge.

The need for enhanced engineering simulation software continues to grow as products become more and more complex – especially projects on the cutting-edge of innovation.

Simulation of Water Flow and Solute Transport as Affected by a Soil Layer Interface and a Subsurface Drainage System using a Numerical Model

Companies can remain competitive by creating smart systems and devices via virtual prototypes. Engineers can link the product’s physical attributes with the systems and embedded software and make sure all pieces work together as planned.

Practical Application | Ansys Systems Overview

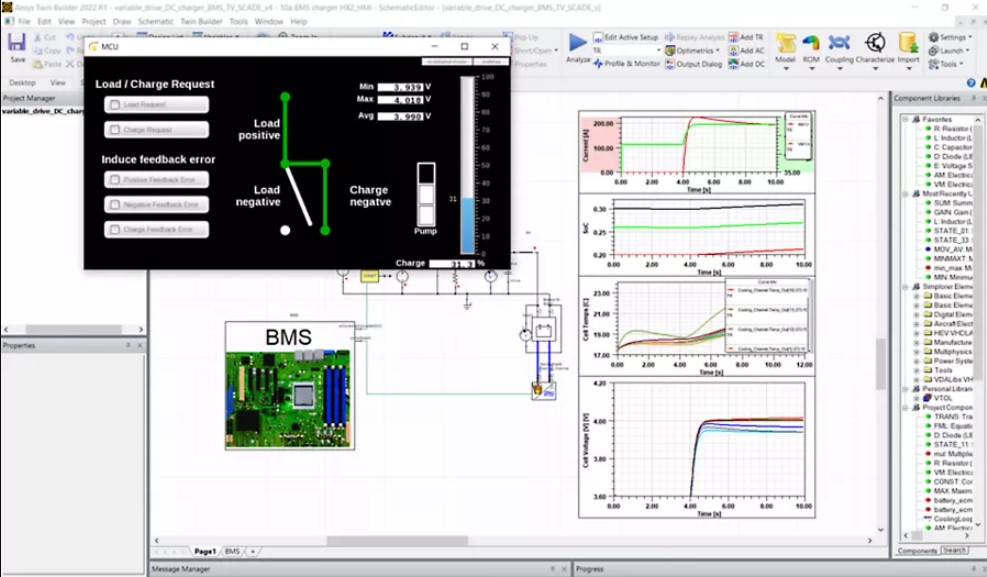

Prototyping via virtual systems means that for today’s complex products, developers can simulate and assemble many types of components, including electronic, electrical, mechanical, thermo-fluid, and embedded software. Use 3-D precision and reduced-order modeling to verify the interaction of multidomain system performance.

Key in power electronics applications is the electric drive system, but optimizing a complex mechatronic system means that expertise, in-depth analysis, and rigorous methodology are required. Optimized components do not guarantee the entire drive system will perform optimally, so a systems simulation approach that integrates individual parts into a common platform is needed.

Power electronic systems are complex applications that present a variety of development challenges in the design of industrial drives, power supplies, energy production equipment, and consumer goods. The analysis and verification of functional safety for electronic control systems in industries like aerospace and defense, are critical to system design and implementation.

ADAS and autonomous vehicles are technologies without precedent in the automotive industry. Vehicle makers and suppliers must deal with five challenges in developing these systems, and Ansys provides solutions to all.

A digital twin is a real-time, virtual copy of an actual operating machine that provides insight into individual product performance and maintenance. The digital twin can predict conditions long before they happen, so you can take corrective actions.

In addition to performance, safety, and cost considerations associated with the electrification of automobiles, aircraft, and industrial equipment, battery capacity (mileage, charge time, and operational lifespan) must be factored into all design equations.

Model, simulate and evaluate high-speed channels and full power delivery systems found in modern high-performance devices with Ansys Slwave. Slwave extracts multi-gigabit SERDES and memory buses with precision, ensuring product compliance for a variety of architectures.

Ansys Medini Analyze implements key safety analysis methods (HAZOP, FTA, FMEA, FMEDA, CMA) in one integrated tool. It supports the efficient and consistent execution of the safety-related activities that are required by applicable regulatory. safety standards.

Ansys Twin Builder is a powerful platform for modeling, simulating, and analyzing virtual systems prototypes. It enables engineering product development teams to verify and optimize performance of their software-controlled, multi-domain systems designs.

A Parasitic Extraction Tool for Electronics Design in the 21st Century. The 3D quasi-static electromagnetic field simulations necessary for the extraction of RLCG parameters from an interconnect structure are easily performed with Ansys Q3D Extractor software.