Overview

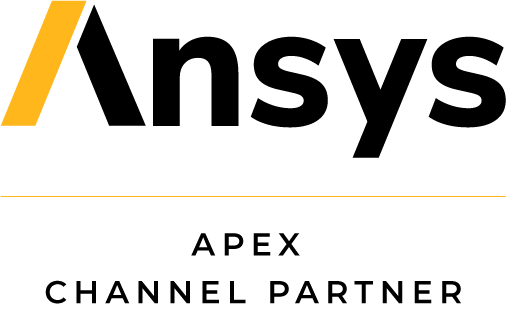

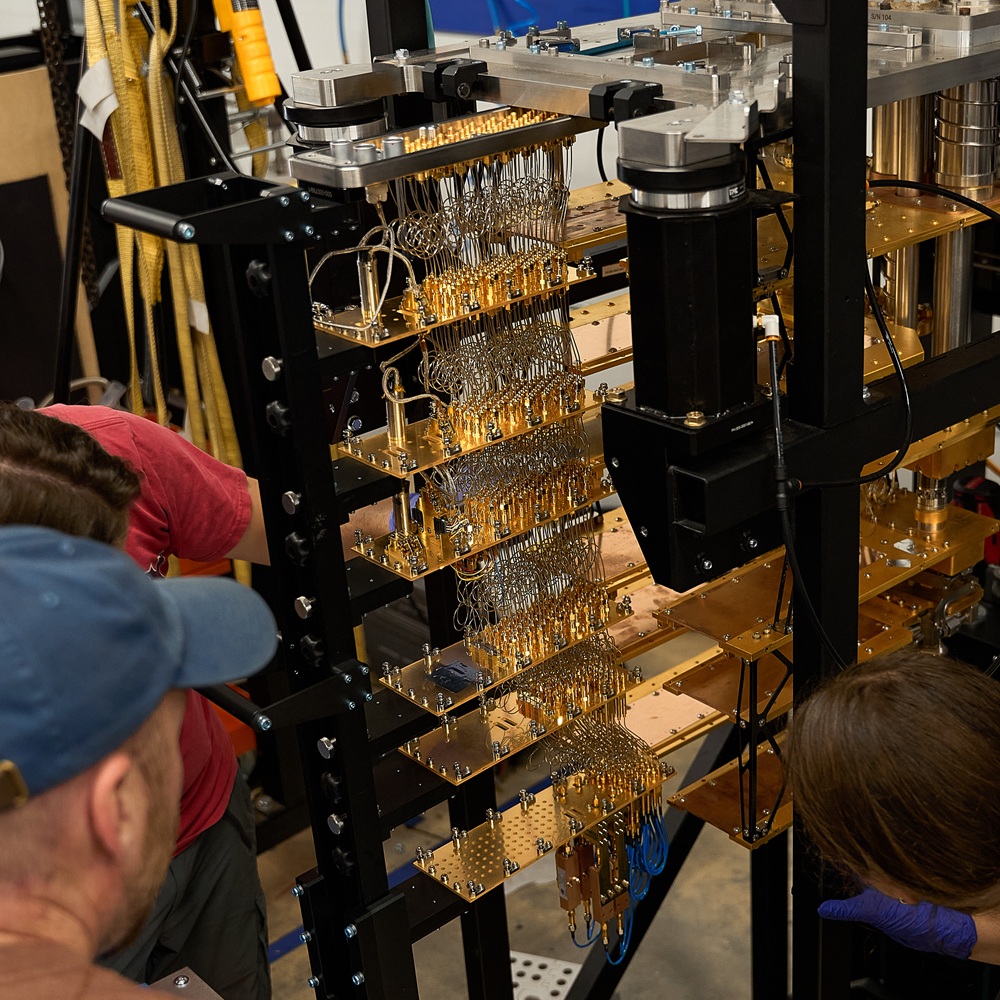

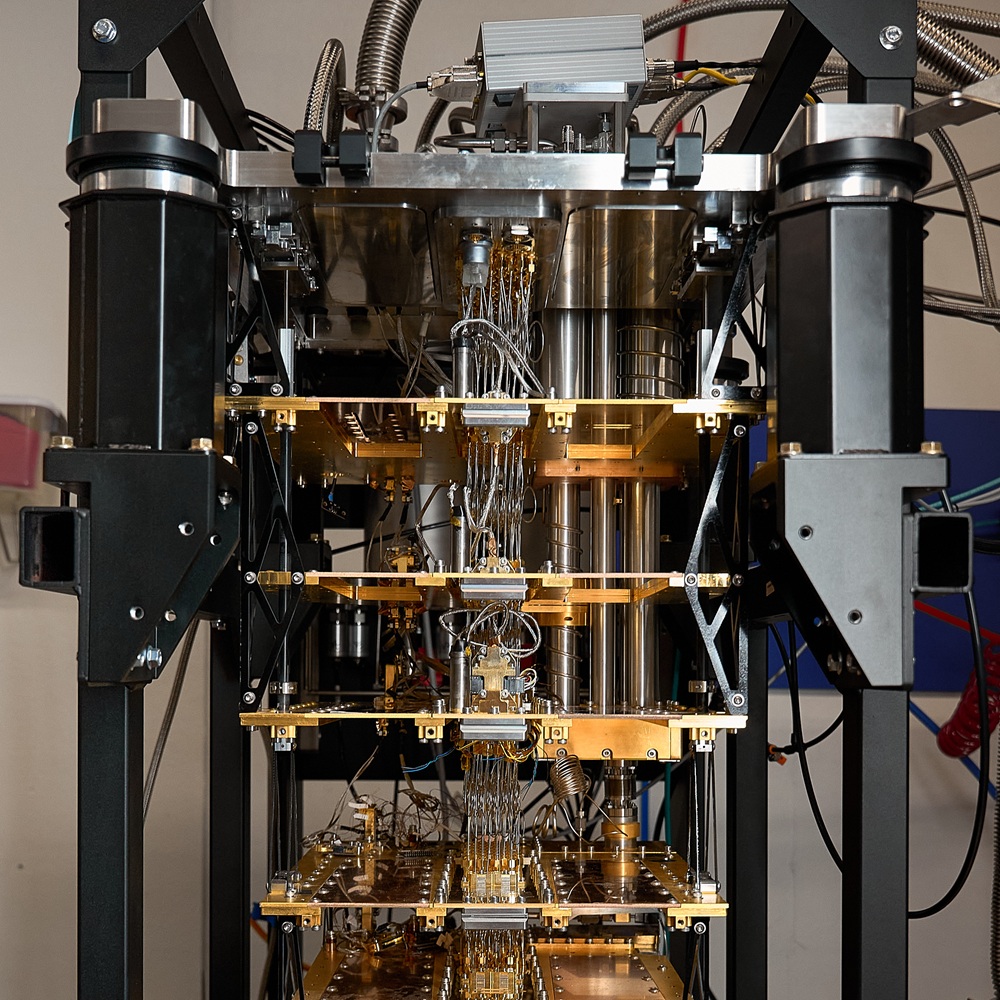

Maybell Quantum is at the forefront of quantum technology development, specializing in next-generation dilution refrigerator design to support cutting-edge quantum experiments. These refrigerators are crucial for maintaining the extreme low-temperature environments necessary for quantum computing and research. By continuously innovating, Maybell Quantum ensures that researchers have access to highly reliable, precision-engineered solutions tailored to their experimental needs

At-A-Glance

Technology Used

Ansys Mechanical

Challenge

Ensuring the next-generation dilution refrigerator design maintained minimal sample plate deflection while accommodating expanded sample mass capacity, without compromising performance or ease of assembly.

Outcomes

- Optimized support structures to meet deflection requirements

- Reduced development time by replacing physical iterations with simulation

- Improved confidence in structural integrity under various load conditions

- Enhanced design efficiency for precision and reliability

- Accelerated innovation through collaboration with SimuTech Group

Maybell Quantum’s Challenge: Dilution Refrigerator Design Optimization

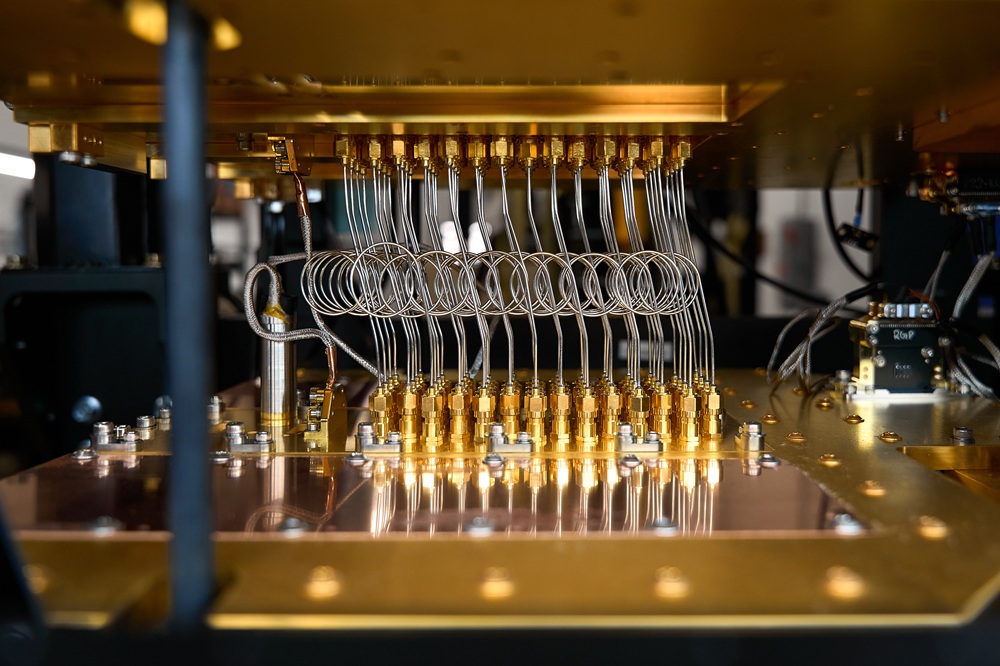

As part of its ongoing advancements, Maybell Quantum set out to develop a next-generation dilution refrigerator designed with expanded sample mass capacity. A critical requirement was maintaining a maximum allowable deflection of the sample plate to ensure the fridge’s ease of assembly and overall functionality. Any excessive deflection could compromise performance, making precise design optimization essential.

The Solution

To address this challenge, Maybell Quantum utilized Ansys Mechanical to enhance its dilution refrigerator design, developing optimized support structures that maintained deflection specifications across various sample load positions. By leveraging advanced simulation capabilities, the team modeled and refined the refrigerator’s structural integrity, ensuring reliable performance under different loading conditions.

The Results

Working with SimuTech Group and using Ansys Mechanical, Maybell Quantum achieved significant advantages:

- Optimized Design Efficiency: The team successfully designed support structures that met deflection requirements without compromising performance.

- Reduced Development Time: By relying on simulation rather than physical hardware iterations, Maybell Quantum shortened the development cycle, allowing for faster innovation and reduced costs.

- Enhanced Performance Reliability: The refined design ensures that the dilution refrigerator maintains its precision and ease of assembly, meeting all necessary functional requirements.

Maybell’s Next-Gen Dilution Refrigerator Design: In Conclusion

By partnering with SimuTech Group and utilizing Ansys Mechanical, Maybell Quantum successfully optimized its next-generation dilution refrigerator design while significantly reducing development time. This collaboration highlights the power of simulation-driven engineering in accelerating innovation and ensuring high-performance solutions in quantum research.

Optimize Your Quantum Research with Simulation-Driven Design

At SimuTech Group, we help innovators like Maybell Quantum refine complex designs with precision. Using advanced simulation tools like Ansys Mechanical, our experts optimize structural integrity, reduce development time, and enhance product reliability. Partner with us to accelerate your engineering breakthroughs and bring high-performance solutions to life.