Strain Gauge Selection Parameters | Strain-Sensitive Alloys

The strain-sensitive alloy employed in the foil grid is the most important factor in determining a strain gage’s working properties.

The strain-sensitive alloy employed in the foil grid is the most important factor in determining a strain gage’s working properties.

Indeed, the strain-sensitive alloy employed in the foil grid is the most important factor in determining a strain gage’s working properties…

…However, the alloy is not always a parameter that can be selected independently. This is because each strain gage series for practical in-field application (designated by the first two or three letters in the alphanumeric gage identification) is intended as a complete system.

That system is made up of a specific foil and backing combination, as well as additional gage construction elements specific to the series (such as encapsulation, integral leadwires, or solder dots).

SimuTech Group Mechanical Testing services offer the following strain gage alloys (alongside the accompanying letter designations):

Constantan is the oldest and most utilized of all current strain gage alloys. This is because constantan possesses the finest overall mix of characteristics for many strain gauge applications.

This alloy, for example, has a high strain sensitivity, or gage factor, that is relatively unaffected by strain and temperature. Its resistivity is high enough to achieve appropriate resistance values in even the tiniest grids, and its temperature coefficient of resistance isn’t excessive.

Furthermore, constantan has a long fatigue life and a reasonably high elongation capability. It should be observed, however, that at temperatures exceeding +150°F (+65°C), constantan tends to drift continuously. When the strain gauge’s zero stability over a period of hours or days is crucial, this characteristic should be considered.

Importantly, constantan may be treated to fit a wide range of test material expansion coefficients via self-temperature compensation (see box at right). For use on test materials with corresponding thermal expansion coefficients (given in ppm/°F), an alloy is supplied in self-temperature-compensation (S-T-C) numbers 00, 03, 05, 06, 09, 13, 15, 18, 30, 40, and 50.

The grid material of choice for measuring very large strains of 5 percent (50 000) or more is annealed constantan (P alloy). Constantan in this form is extremely ductile and can be strained to >20 percent in gage lengths of 0.125 in (3 mm) and longer.

It’s worth noting, though, that under high cyclic loads, the P alloy will show some permanent resistance change with each cycle, resulting in a zero shift in the strain gage.

P alloy is not usually recommended for cyclic strain applications because of this property, as well as the risk of premature grid breakdown with repeated stressing. For application on metals and polymers, P alloys with S-T-C values of 08 and 40 are available.

When only dynamic strain measurements are required — that is, when a stable reference zero is not required — isoelastic (D alloy) has several advantages.

Superior fatigue life compared to A alloy and a high gage factor (about 3.2) that enhances the signal-to-noise ratio in dynamic testing are two of the most notable benefits.

Self-temperature compensation does not apply to D alloy. Furthermore, the alloy’s thermal output is so high (about 80/°F (145/°C) that it’s not usually suitable for static strain measurements.

However, D alloy can be utilized in special-purpose transducers that require a high output and can benefit from a full-bridge configuration to achieve appropriate temperature adjustment inside the circuit.

With its wide range of applications, modified Karma, or K alloy, is a significant member of the strain gage alloy family. This alloy has a long fatigue life and is extremely stable, making it the best choice for reliable static strain measurements over long periods of time (months or years) at room temperature or shorter periods at elevated temperatures.

It’s best for extended static strain measurements in the –452° to +500°F (–269° to +260°C) temperature range. Encapsulated K-alloy strain gages can be exposed to temperatures as high as +750°F (+400°C) for brief periods of time. At high temperatures, an inert environment will improve stability and lengthen the useful gage life.

K alloy, among other things, has a substantially flatter thermal output curve than A alloy, allowing for more precise rectification of thermal output mistakes at severe temperatures. For use on materials with varying thermal expansion coefficients, K alloy, like constantan, can be self-temperature-compensated.

However, the S-T-C numbers available in K alloy are at times, limited by temperature thresholds. When a temperature-compensated gage with environmental capabilities and performance attributes not available in A-alloy gages is required, K alloy is the standard choice.

Because soldering directly to K alloy is difficult, a duplex copper addendum has become a standard on all SimuTech Group open-face strain gages made with K alloy.

Depending on the available tab space, the duplex copper addendum is a perfectly produced copper soldering pad (DP) or dot (DD). DP or DD is part of the nomenclature for all K-alloy gages that do not include leads or solder dots (in place of, or in addition to, the option specifier).

For clients with customized alignments, the exact style of copper treatment will be advised.

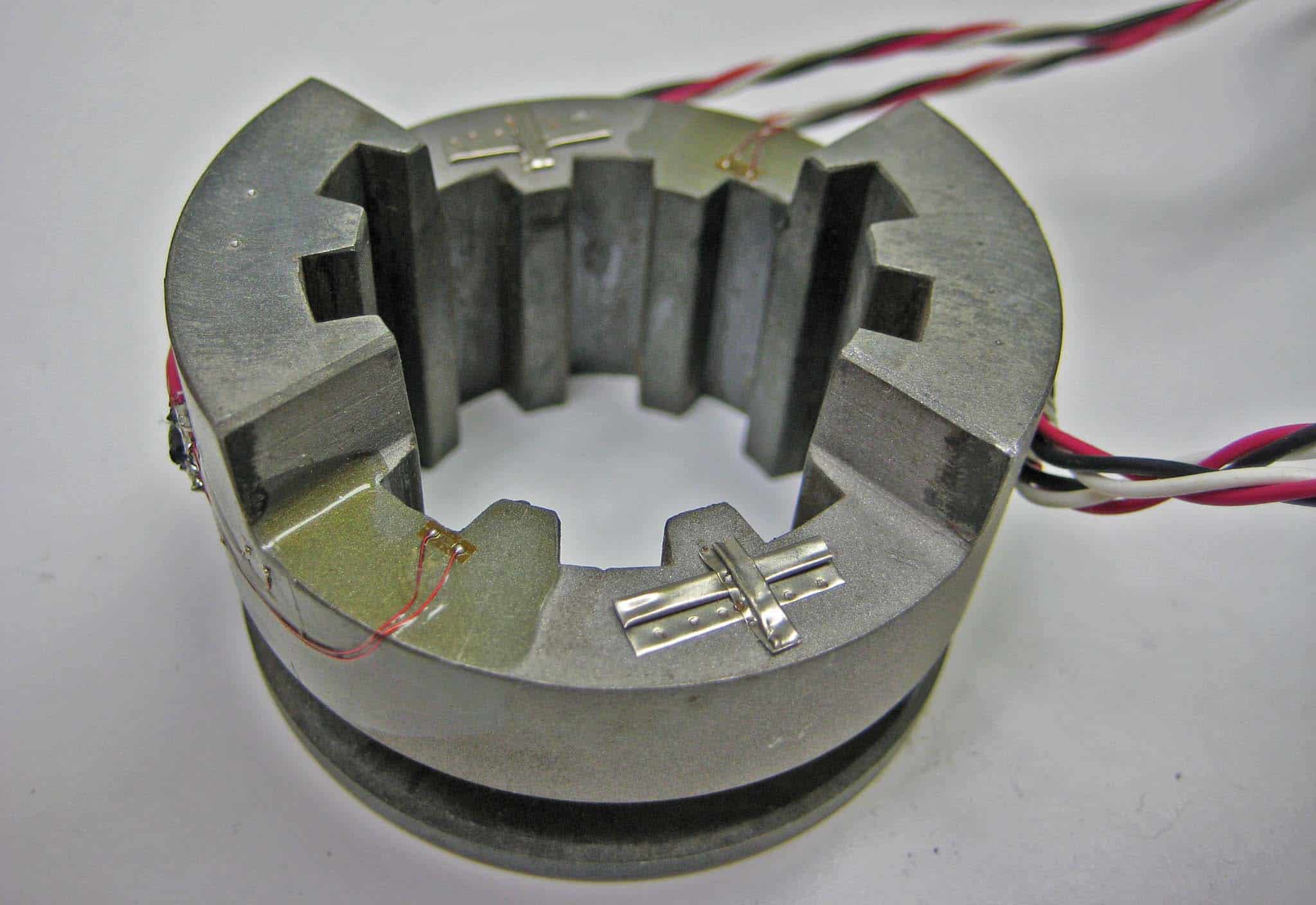

Strain gauges are ideal for verifying stress and displacement simulation models. The strain measurements are taken at specific locations and correlated with the simulation results.

Modeling assumptions such as boundary conditions, contacts, and loads may be updated to make the simulation better fit the observed behavior.

Once the model accurately reflects the measurements, more detailed information about the system can be inferred.

In addition, simulations of the modified system can be used to predict behavior with confidence.

SimuTech Group specializes in both strain gage measurement as well as simulation, allowing seamless support when conducting investigations.

For new, refurbished, or reverse engineered turbine blades (buckets) to ensure that natural frequencies are within specifications.

Determine the natural frequencies and mode shapes of a rotor train as it twists about the axis of rotation.

Identify the root cause of noise and vibration problems in machinery via ODS, spectral, order tracking or joint time frequency analysis.