Workbench Meshing Techniques | Ansys Mechanical Webinar:

This webinar covers the fundamentals of workbench meshing techniques in Ansys Mechanical:

- Introduction to Meshing

- Meshing Methods

- Global Mesh Controls

- Local Mesh Controls

Tetrahedral vs. Hexahedral Meshing Techniques

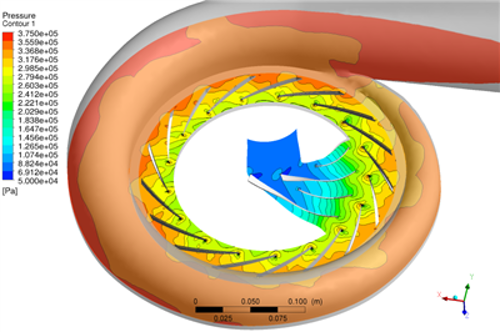

The two primary meshing techniques are as follows. We are referring to 3D models in this context:

- Tet, short for tetrahedral element meshing

- Mesh of hexahedral elements, or “hex”

In comparison to tet elements, hex or “brick” elements typically produce more accurate results at lower element counts. The optimum option may be tet elements if the geometry is intricate. There are further methods that can give you more mesh control, but these default or automatic meshing techniques might be sufficient to get you where you need to go.

Hybrid Meshing Techniques

By combining hex and tet elements, the Multizone method in Mechanical enables you to mesh various portions of the geometry using various techniques.

As a result, you can create more local control meshes and perform less geometry preparation.

For instance, recreating a pipe connection shape utilizing the hybrid meshing features of Ansys Mechanical

Mesh Sweeping in Ansys

Sweep meshing involves the mesh actually “sweeping” through the volume and faces in order to produce a useful mesh with standard dimensions.

The sort of analysis (explicit or implicit) or physics you are solving for, as well as the amount of precision you want to attain, usually determine the mesh method to utilize. Cartesian meshing and stacked tets are two additional techniques that are employed for particular studies like additive manufacturing.

Manipulate Local Meshing with Ansys

Instead of a global mesh that meshes the entire CAD with the same technique, Ansys Mechanical gives you the ability to manipulate local meshes. Local scaling, refinement, and sphere of influence defeaturing of the geometry are some examples of local meshing controls.

Consider the frame of a motorcycle. The overall geometry may benefit from a generic mesh technique, but the weld and bolted connections may require a separate solution. By using local meshing settings, you can mesh the area around these points more precisely rather than the entire section, which would require more time to solve.

A quality mesh will meet your needs in terms of analysis type, accuracy level, and time as well as element quality and aspect ratio.

Mesh Controls Mesh Controls allow for a more accurate mesh.

- For more on Ansys Mosaic Meshing Capabilities

- For more on Ansys Fluent Meshing Capabilities

- For more on Ansys Polyflow Meshing Capabilities

- For guidance on Ansys Post-Processing

- For Support on performing ‘EKILL‘ in Workbench

- APDL Command Objects post-Spectral Analysis

- For Separating DB Database Files from RST Files