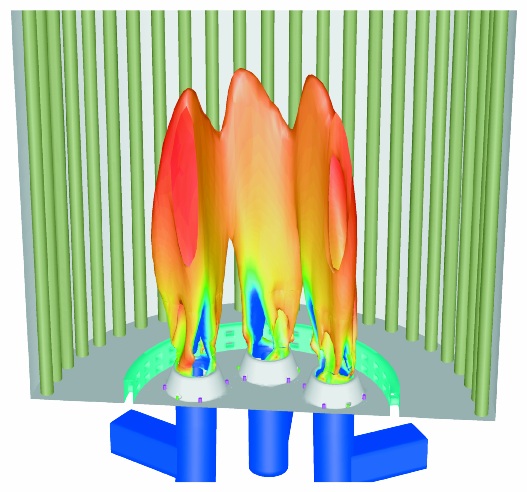

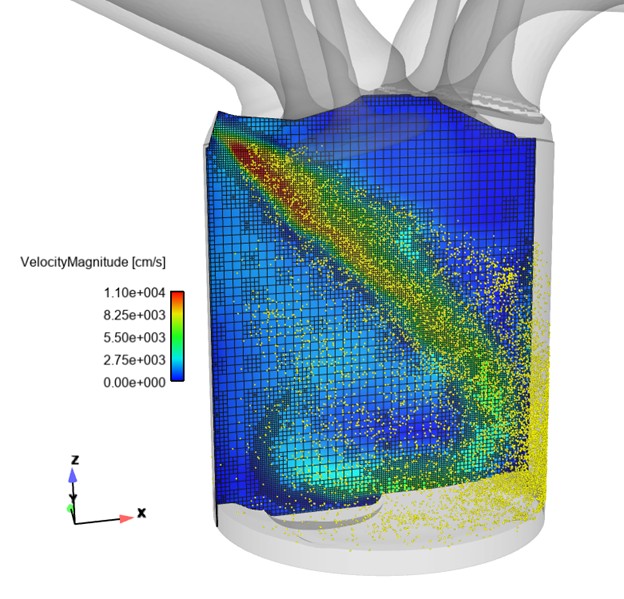

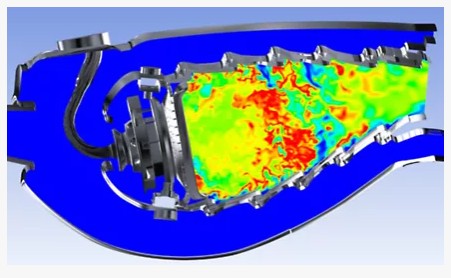

Reacting Flow and Combustion Simulation Consulting

Capture the complex interplay of turbulence, heat transfer, and chemical kinetics with reacting flow CFD — essential for accurate modeling of combustion, catalysis, electrochemical systems, and CVD processes.