INFLO Technique Auto Shutoff Valve (ASV): Background

INFLO Technique, a Québec-based startup specializing in high-pressure fluid-control equipment, set out in June 2024 to design a compact auto shutoff valve (ASV) for U.S. Navy air and nitrogen service up to 3000 psi. The valve had to comply with ASTM F1793 and close instantly if downstream pressure dropped, performance which is mission-critical for shipboard safety. To meet an aggressive schedule and conserve startup resources, INFLO adopted a simulation-first workflow and partnered with SimuTech Group for software procurement and technical support.

At-A-Glance

Technology Used

- Ansys CFX

- Ansys Mechanical

Challenges

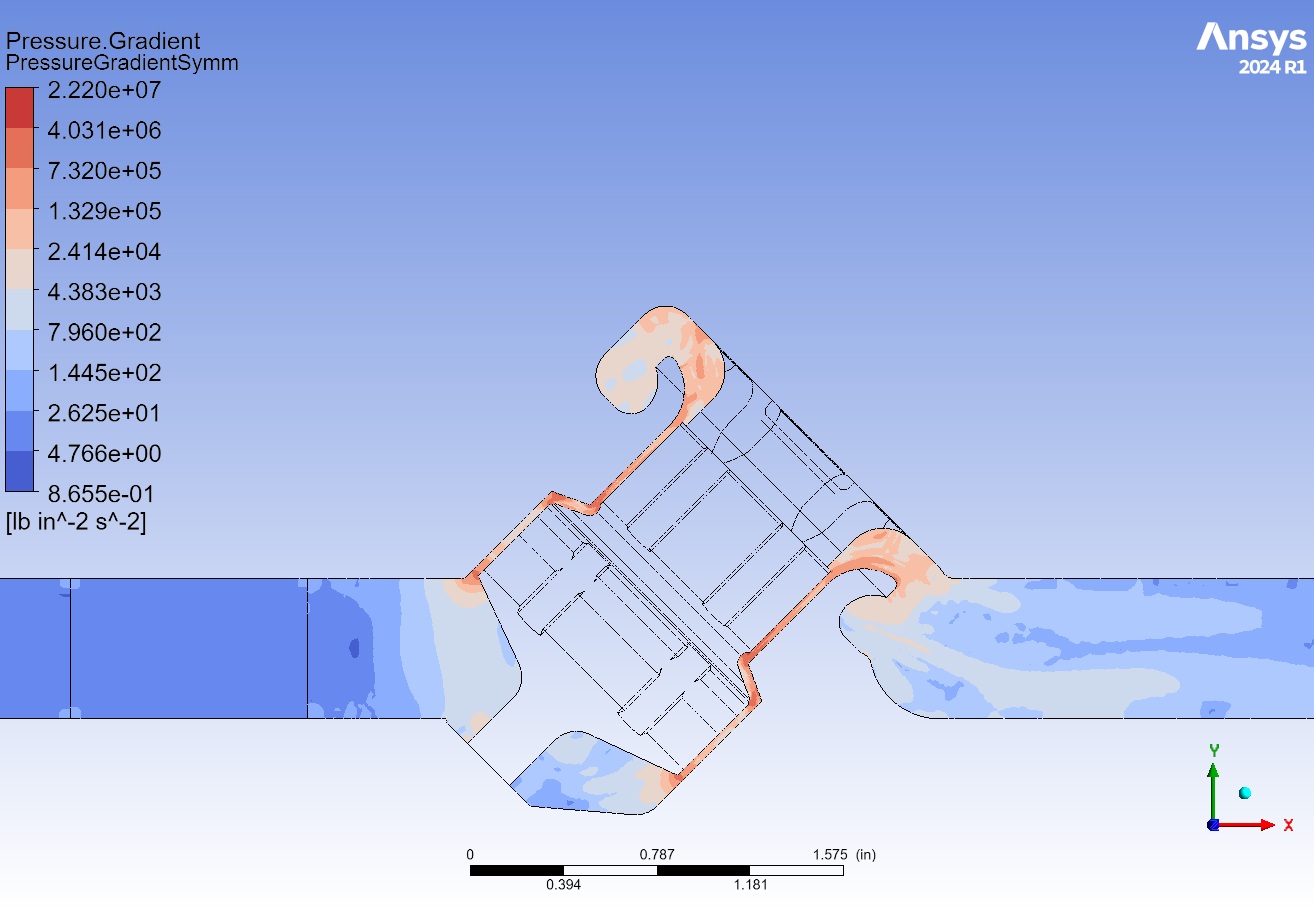

- Predict unknown disc forces and pressure drop under various flow conditions.

- Deliver a qualified auto shutoff valve on a startup timeline.

Outcomes

- 3-6 months schedule reduction

- Single prototype iteration

- ASTM-qualified valve

- Scalable simulation workflow for future programs

The Problem

Designers lacked reliable data on the transient forces acting on the valve’s obturating disc. Without accurate force predictions, they risked multiple costly prototype cycles to balance spring preload, flow set-point, and structural margins for the auto shutoff valve.

The Solution

- Software acquisition: SimuTech Group arranged an affordable Ansys license bundle (Ansys CFX for CFD and Ansys Mechanical for structural checks) tailored to INFLO’s startup budget.

- Expert support: INFLO’s lead engineers leveraged SimuTech’s rapid-response support twice during the project to refine mesh strategy and extract accurate disc forces, resolving pressure-drop discrepancies between simulation and early bench tests.

- Single-iteration prototype: Single-iteration prototype: Armed with reliable CFD results, INFLO produced only one set of disc prototypes before finalizing the auto shutoff valve design, ready for delivery months ahead of schedule.

The Benefits

- 3-6 months faster to market thanks to simulation-driven design that eliminated up to three extra prototype loops.

- Lower development cost by avoiding repeated machining, test-stand time, and engineer labor.

- Confidence in compliance due to virtual pressure-drop and force predictions matching physical tests within the expected range, ensuring ASTM qualification on the first try.

- Foundation for growth: positive experience “cemented a long-term relationship” and prompted plans to expand the license pool and invest in SimuTech training services.

With SimuTech’s guidance we trimmed three to six months off development, going from CFD to a qualified, single-iteration auto shutoff valve in record time.

Louis Lacasse

Lead Engineer, INFLO Technique

INFLO Auto Shutoff Valve: In Conclusion

With a fully designed and produced auto shutoff valve delivered months ahead of schedule, INFLO can now shift resources to scaling production, pursuing new naval and industrial contracts, and fast-tracking its next generation of fluid-control products, confident that simulation-driven design will keep future timelines just as lean.

Ready to Save Time and Money?

Shave months off your next design. Talk to SimuTech Group about software, training, and support packages that accelerate innovation and de-risk product launches. Let’s get your project moving. Contact us today!