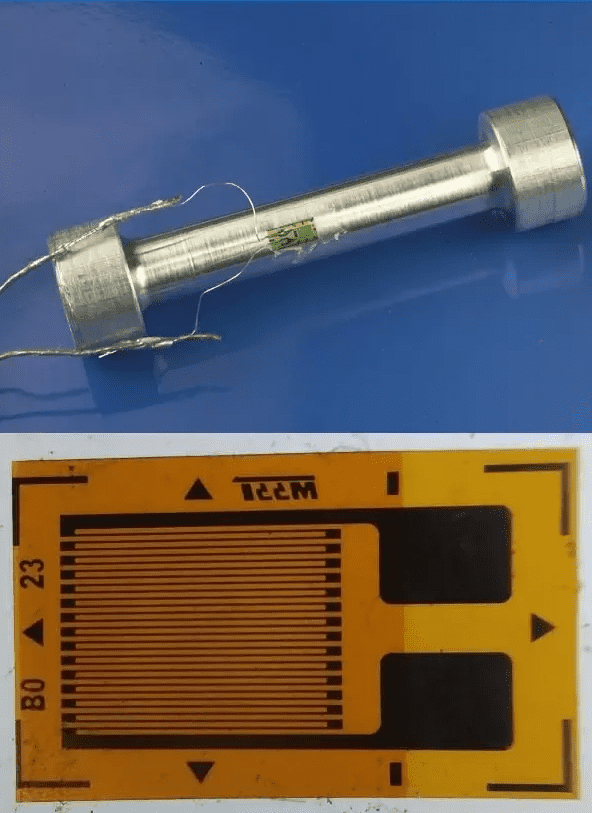

Strain Gauge Backing Material I: Polyimide E

Strain Gauge polyimide E backing is a robust and flexible carrier that may easily be molded to meet small radii.

Polyimide-backed gages are also less susceptible to mechanical damage during installation due to the high peel strength of the foil on the polyimide backing.

Additionally, Polyimide is a good backing material for general-purpose static and dynamic stress research due to its simplicity of handling and adaptability for use over a temperature range of –320° to +350°F (–195° to +175°C).

Strain Gauge Backing Material II: C2 & L2 Laminated Polyimide

Modern strain gauges offered by SimuTech Group also offer C2- and L2-laminated polyimide backings, which are robust and flexible carriers with an encapsulating layer to preserve the grid.

These backings are commonly encountered with SimuTech Group’s mechanical engineers for pre-leaded and pre-cabled strain gages, and can conform to a small radius or fillet.

In addition, this backing can withstand significant elongations and can be utilized to detect plastic strains of more than 20%. Common Strain Gauge types such as EA-, CEA-, EP-, EK-, S2K-, N2A-, and ED-Series strain gages, each have a polyimide backing.

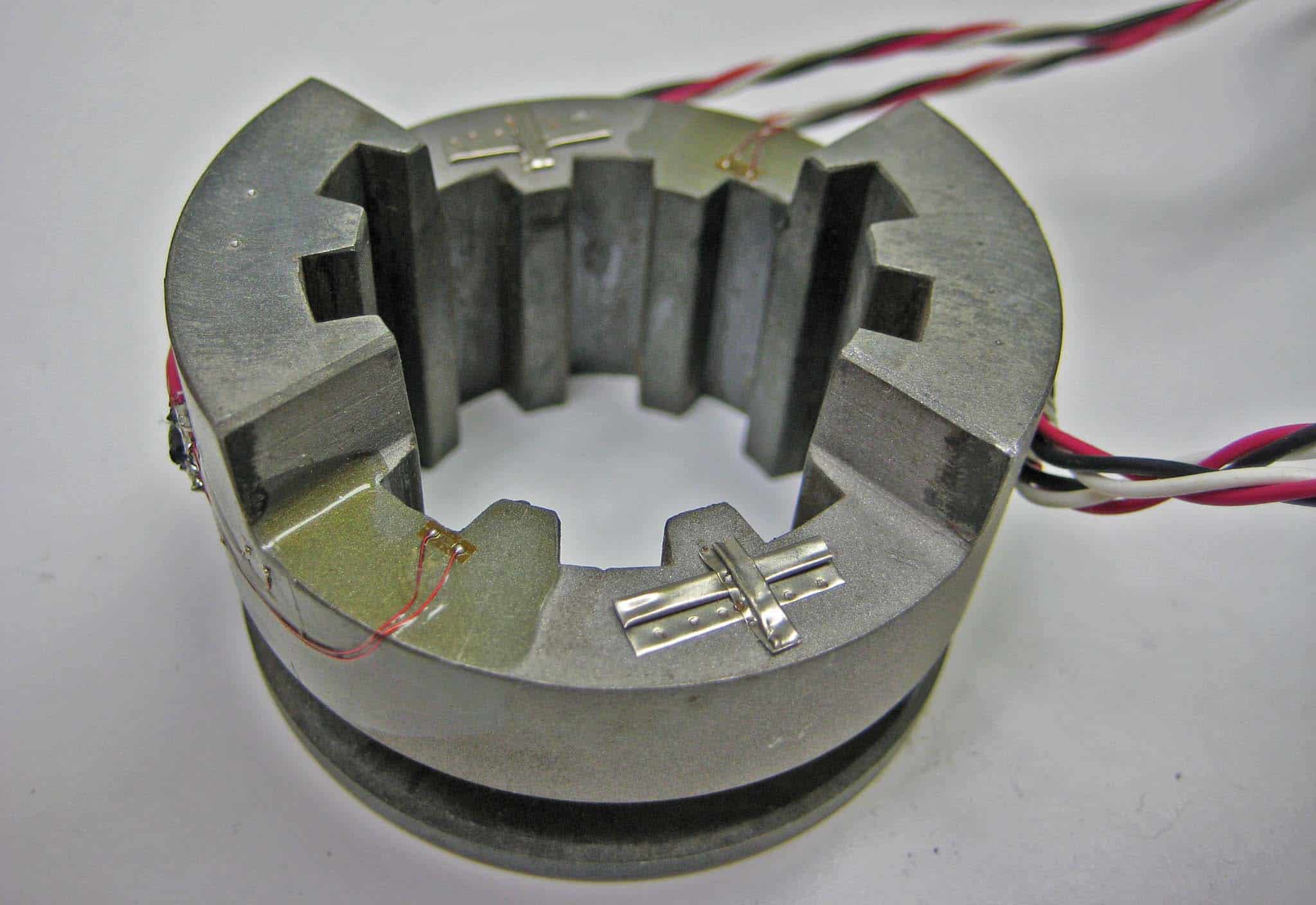

Strain Gauge Backing Material III: Glass-Fiber Reinforced Epoxy-Phenolic

The glass-fiber-reinforced epoxy-phenolic backing material is the best choice for great performance throughout the widest temperature range.

From –452°F to +550°F (–269°C to +290°C), this backing can be used to quantify static and dynamic strain. The highest temperature limit can be increased to +750°F (+400°C) in short-term applications.

However, the maximal elongation of this carrier material is restricted to roughly 1% to 2%. The following gage series use reinforced epoxy-phenolic backing: WA, WK, SA, SK, WD, and SD.