Electronics Cooling | Active and Passive Cooling

Controlling temperature is critical to the efficiency, safety, and durability of many products and processes. With Ansys simulation you can improve thermal management of products and processes. By enabling engineers to understand the root cause of thermal problems, and identifying electronics active and passive cooling thresholds, thermal/electronic overheating issues can corrected in the pre-design stages.

In addition, simulation makes it practical to evaluate a wide range of alternative designs. Including, design optimization to ensure product safety under many different operating scenarios.

Single physics solutions with relatively simple physical models are sufficient for some thermal management challenges. However, many applications do not meet all the assumptions on which the simpler models are based.

Why Thermal Analysis Matters

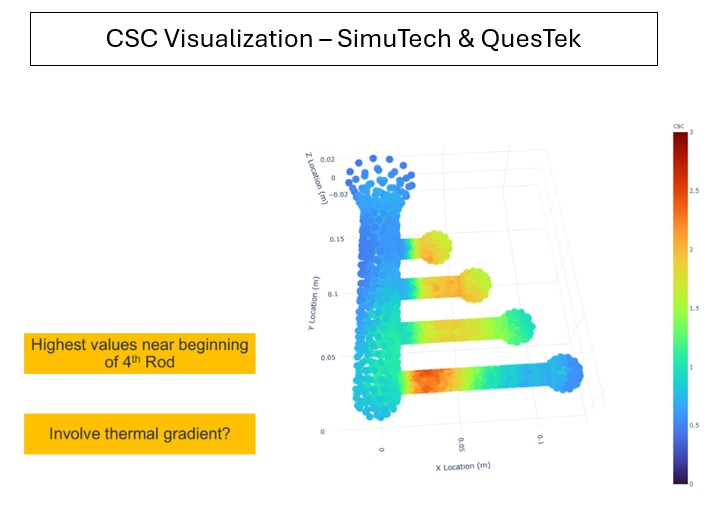

Most products and processes have a thermal comfort zone, a range of temperatures in which they operate most efficiently. Operating outside this zone may cause problems such as failures of critical components. Other potential issues include generation of thermal mechanical stresses which may also lead to early failure.

Investigating thermal effects in the laboratory is often not practical beyond a few sets of conditions. As it is, laboratory testing is time-consuming and costly to replicate complex thermal scenarios.

However, simulating the thermal performance of a product early in the design phase can save large amounts of time and money. Through proper planning, engineers can achieve optimal design of early prototypes from a thermal management standpoint.

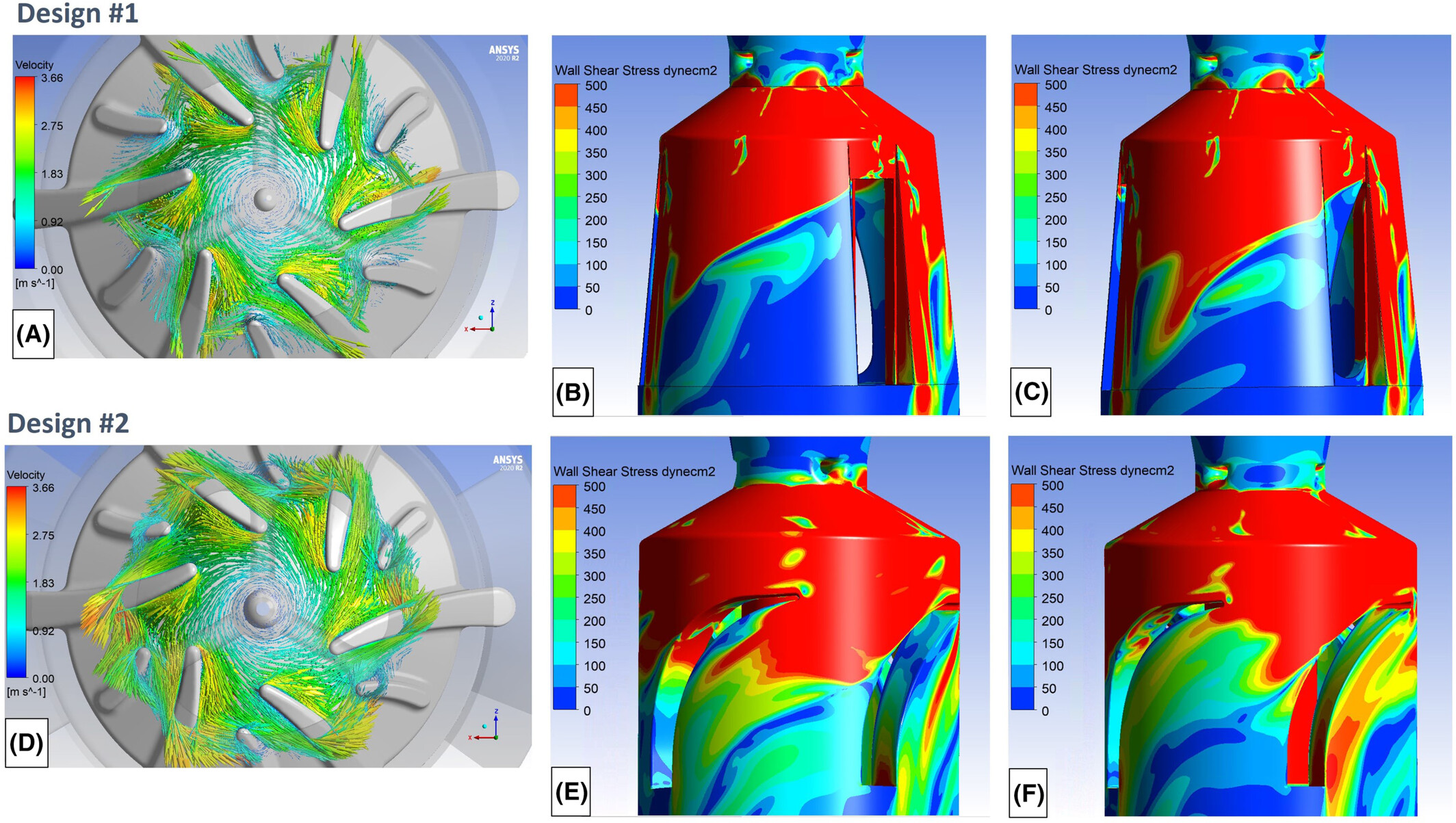

As a result, this would reduce the need for additional prototypes that might otherwise be required to diagnose and correct thermal issues. Simple computational fluid dynamics (CFD) software can be used to analyze thermal issues. A common application includes determining how/how much heat is transferred through a fluid.

However, many problems are more complex. For example, those that involve multiple mechanisms of heat transfer. Or, where heat is transferred through both solids and structures. Engineers often need to understand how heat is transferred by several different mechanisms. Often through a complicated interconnected system in order to understand how their product or process will perform under a given set of conditions.

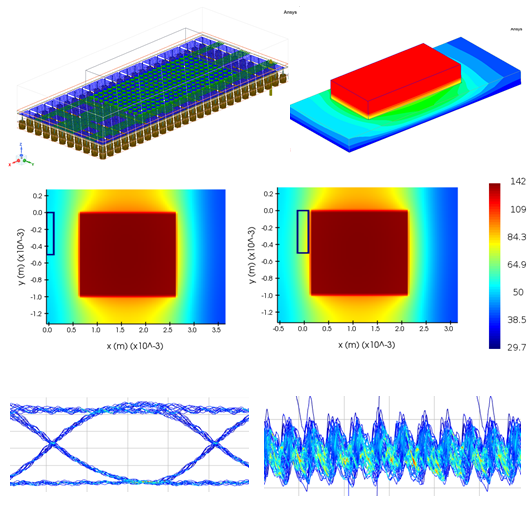

The Ansys Icepak Thermal Solution

With the Ansys Icepak software suite you have powerful electronic cooling solutions at your fingertips. Ansys Icepak accurately predicts airflow, temperature, and heat transfer. This software is designed specifically for high and low frequency electronics, power electronic components, and printed circuit boards (PCBs).

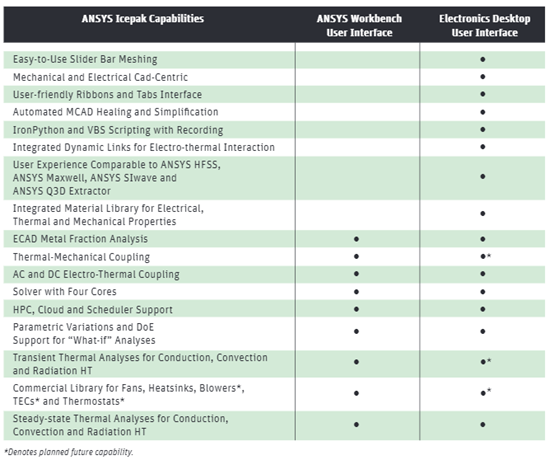

With CAD-centric and Multiphysics user interfaces, Ansys Icepak facilitates the solving of today’s most challenging thermal management problems in electronics products. It uses sophisticated CAD healing, simplification and metal fraction algorithms that reduce simulation times. All-the-while, providing highly accurate solutions that have been validated against real-world products.

The solution’s high degree of accuracy results from the highly automated, advanced meshing and solver schemes. This robust process simulation ensures a true representation of the electronics application.

You can learn more about thermal management and the Ansys Icepak software solution through our Official Ansys Icepak Introductory Training Course – “Ansys CFD 301.” You will learn how you can take advantage of a thermal management simulation tool. And perhaps more importantly, better understand and predict product behavior in different, real-life situations.