Structural Analysis: Vital in Everyday Engineering

In essence, structural analysis is the process of studying a structure, which can take one of many forms, with the goal of understanding how it will behave under certain loading conditions. Many objects that are part of our lives, from something as small as a toothbrush, to larger things like cars and buildings, were engineered with structural soundness in mind in order to serve their intended purpose, time and time again.

From Cell Phones to Cars: the “Impact” on Everyday Objects

If you have ever accidentally dropped your cell phone, you may have wondered how much damage was actually done to it. Maybe you have even asked yourself:

- What specifically has to happen upon impact for the screen to shatter?

- What happens to the electronics inside?

- How exactly does a protective case limit the damage, and by how much?

These are all questions that have pretty complex answers, which can thankfully be found through structural analysis! Gaining a better understanding of the materials and construction of the phone, as well as the physics of the impact, plays a crucial role in answering these questions.

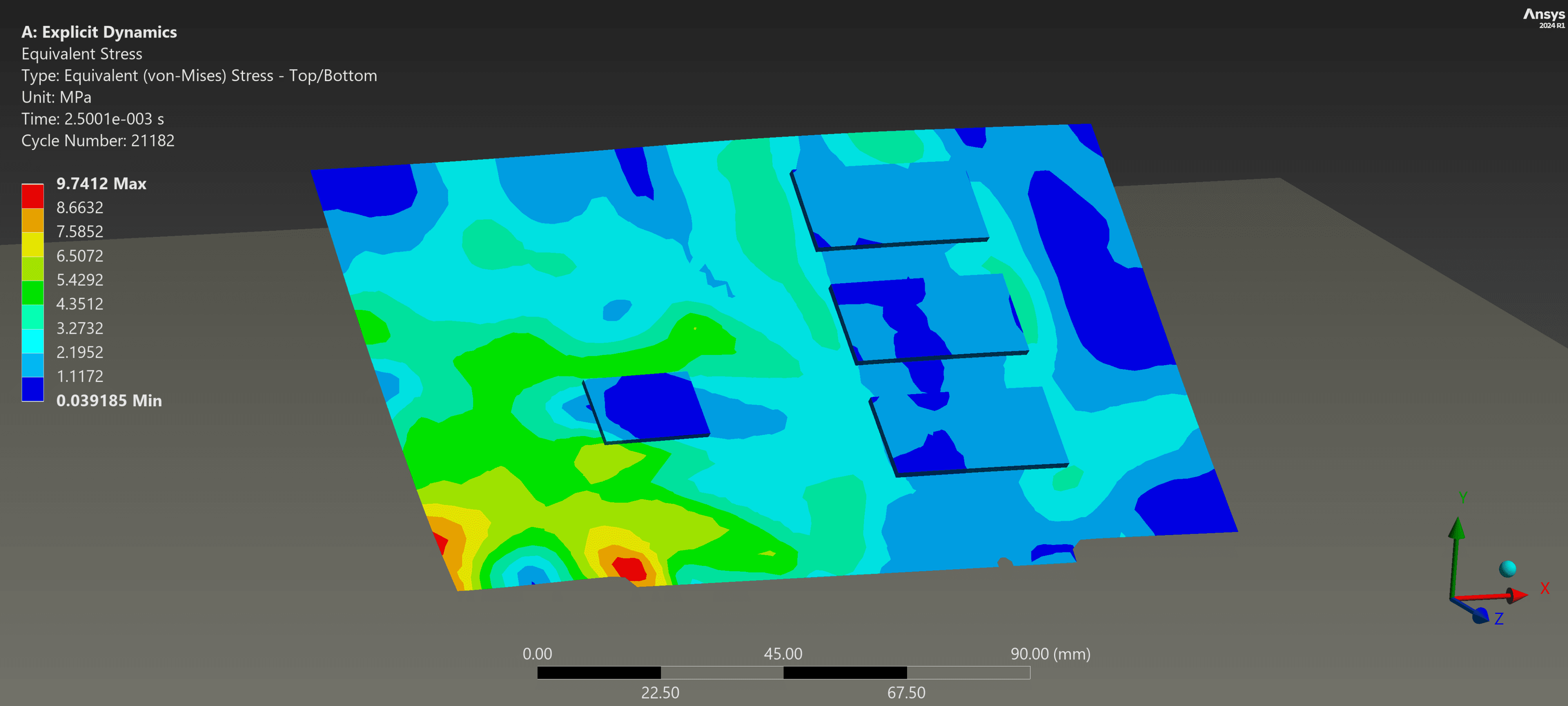

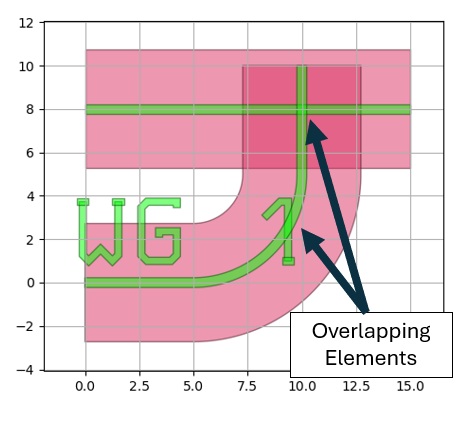

Impact Test Example

Let’s consider an example of an impact test on a circuit board (Figure 1). Much like how a tuning fork vibrates when you strike it against a surface, the circuit board will also vibrate on impact, but much more randomly. This can all be analyzed to get a sense of how close the circuit board will get to structural failure.

Structural Analysis in Car Safety

When you buy a car, you may be aware that it went through rigorous safety testing before entering the market. But, what are manufacturers really looking for with this testing? What information do they get from running so many different kinds of tests (e.g., frontal crash with full or partial overlap, side crash, roof crush, seats testing, headlight testing, crash prevention system testing)? What else in the car keeps occupants safe in addition to just the seatbelts and airbags?

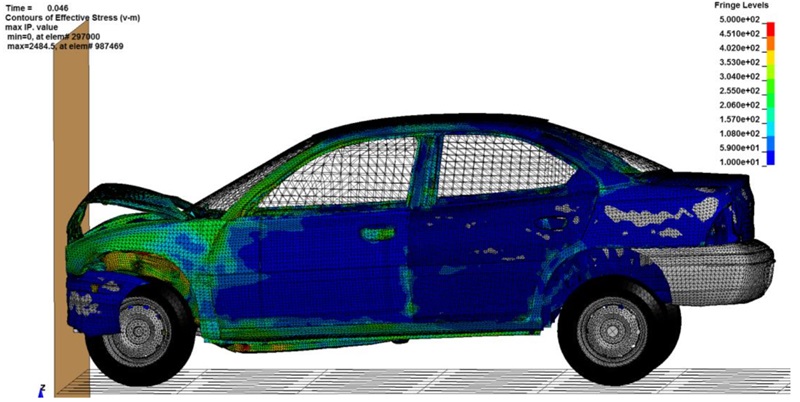

Crumple Zone Analysis

There actually is another crucial safety feature in cars during a crash: the crumple zone (Figure 2). Crumple zones are areas in the car designed specifically to crumple on impact, so that the car takes on as much of the impact force in a crash as possible in order to limit injury to the occupants. This, and many other features that are studied in crash tests, are all part of a very complex structural analysis that serves to make cars safer for everyone.

The Role of Advanced Materials

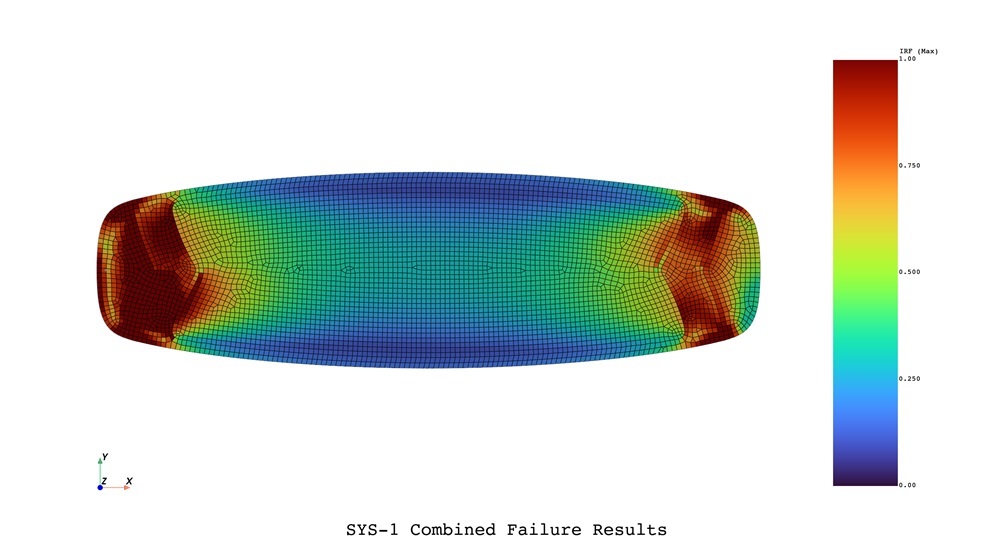

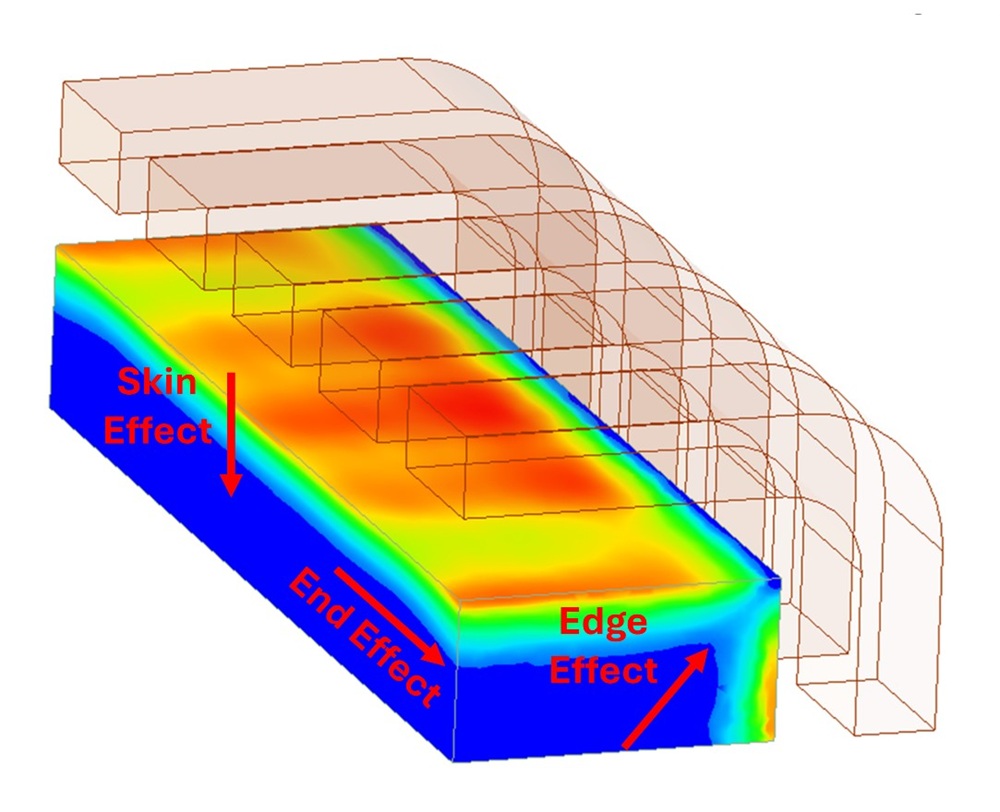

Finally, let’s explore the idea of advanced materials such as composites. Structures made from composites can be just as strong as those made from steel while also being much more lightweight! In fact, composites are regarded as an excellent option for high-performance sporting equipment, such as skis, bicycle frames, hockey sticks, tennis rackets, and kiteboards (Figure 3).

Analyzing Composites

Since composites by their very nature are a combination of different materials, this fact alone introduces its own complexity to the structure. Determining failure in a composite involves a very different, much more exhaustive set of rules than in more traditional materials such as metals. Fortunately, there are powerful tools for engineers to be well equipped to study composites and perfect their designs before releasing them into the market.

Summing It Up

In summary, structural analysis can be applied to anything and everything that undergoes physical loading. Such insight on structural performance is the basis on which the things we use can serve to improve our everyday lives.

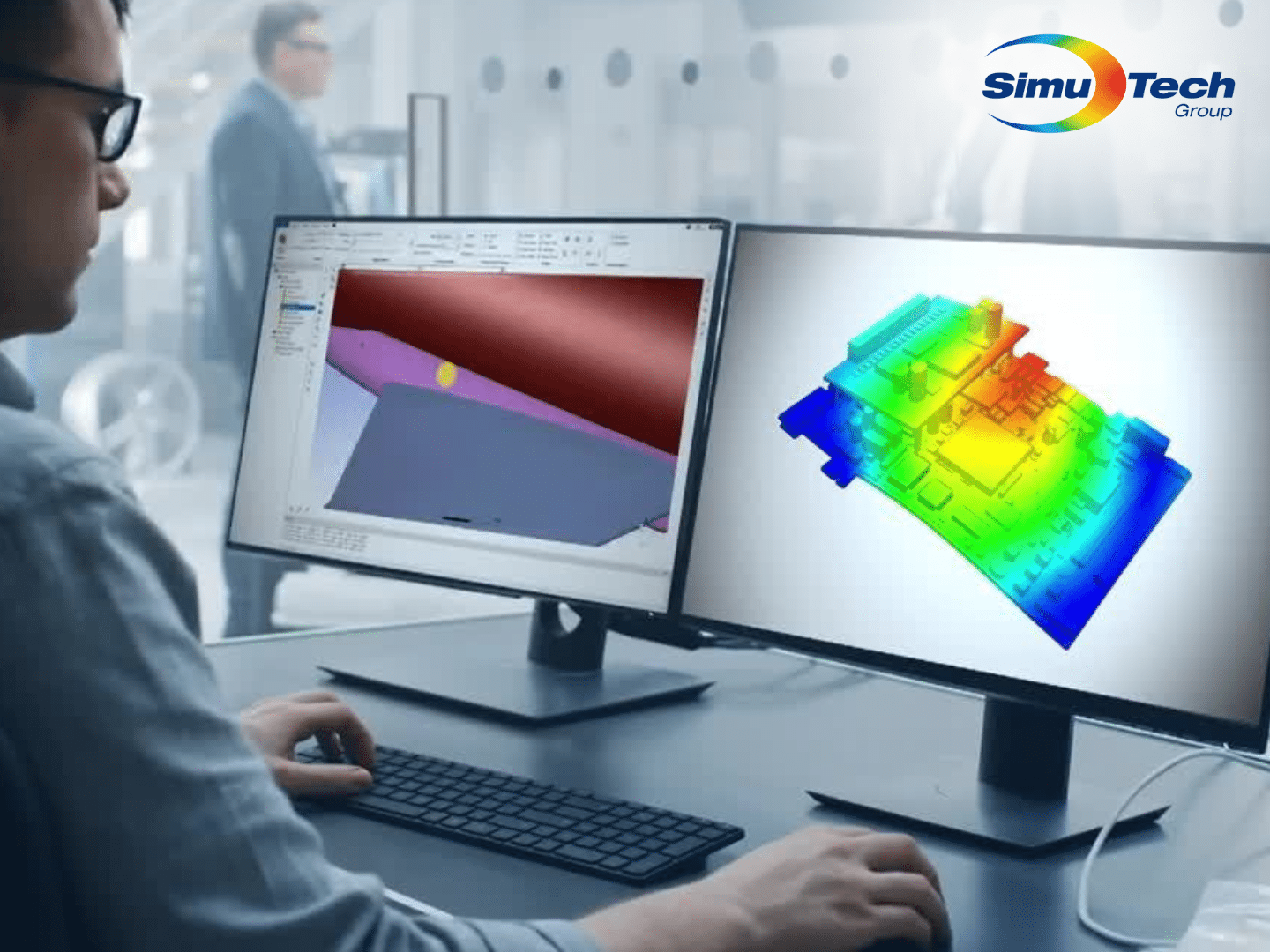

Next Steps for Engineers

Utilizing advanced simulation software like Ansys Mechanical, LS-DYNA, and Sherlock can significantly enhance the accuracy and efficiency of predicting and addressing complex structural analysis situations. These tools enable engineers to model and analyze the behavior of materials and components under various conditions, providing valuable insights that can inform design decisions. By incorporating these simulations early in the design process, companies can save time and money by identifying potential issues before physical prototypes are created, ultimately leading to more robust and reliable products.

Interested in learning more about Ansys simulation software or speaking with an expert about Structural/FEA Consulting, mentoring or a testing project?

About the Author

Alex Dondish, M.S. Mechanical Engineering

FEA Engineer

Alex is an FEA engineer analyst with specialization in advanced composite materials and primary interests in the automotive and aerospace industries. He has experience with various cutting-edge software and hands-on materials testing and manufacturing. Alex sits in SimuTech Group’s Toronto office, is an avid language learner and holds a Bachelor of Engineering and a Master of Science in Mechanical Engineering from York University.

Related Content

FEA, Structural Analysis & Thermal Consulting Services

Ensure the structural integrity, performance, and reliability of your designs with our expert FEA consulting services.

Ansys Finite Element Analysis (FEA) Software

Ansys software for structural analysis allows you to solve your most complex structural engineering projects and make superior design decisions more quickly.

Engineering & Simulation Webinars

View upcoming and on-demand webinars while learning about simulation software features, updates and best practices.

Industry Solutions

SimuTech Group provides industry-specific capabilities and expertise that deliver the flexibility and scalability you need for your specific projects.