Synchronic Vibration and Turbomach “Rubs” or Streaks

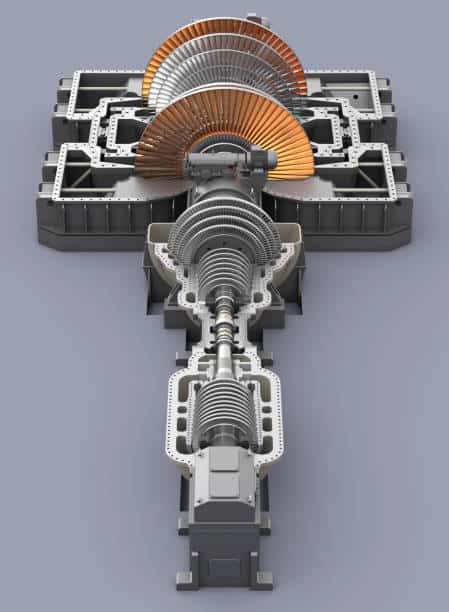

Regardless of the type of rotating machinery, synchronic vibration is typically present. Common causes or sources of this vibration component include mass unbalance, mechanical bows, thermal bows, shaft surface runout, and rubs. Consequently, when vibration levels from one of these sources becomes dangerously high, corrective action must be taken by engineers.

In some cases, the synchronous vibration levels do not merely increase, remaining at a constant amplitude and phase angle. Rather, significant variations of the 1X vectors occur where the amplitude may assume a cyclic trend that alternately increases and decreases while the phase changes as well.

In addition, the plot types typically used to observe this activity are trend files (1X amplitude and phase versus time), polar plots, and shaft orbits. These allow the diagnostician to determine, among other things, the magnitude and period of the cycles. This engineering article, co-sponsored by SimuTech Group engineering experts, reviews two different mechanisms whereby 1X amplitudes and phase variations can be observed: light streaks and a more recently described phenomenon, known as the Morton Effect.

Turbomachinery Exploration 1 – Light Streaks

There are a variety of streaks that can occur in machinery, with different rub locations (seals, bearings, etc.), different initiating conditions, and different rub classifications (full annular, partial, bouncing, etc.).

Here, we confine our discussion to light streaks that create a thermal bow condition. It is these types of streaks that often result in a modulating synchronous vibration response.

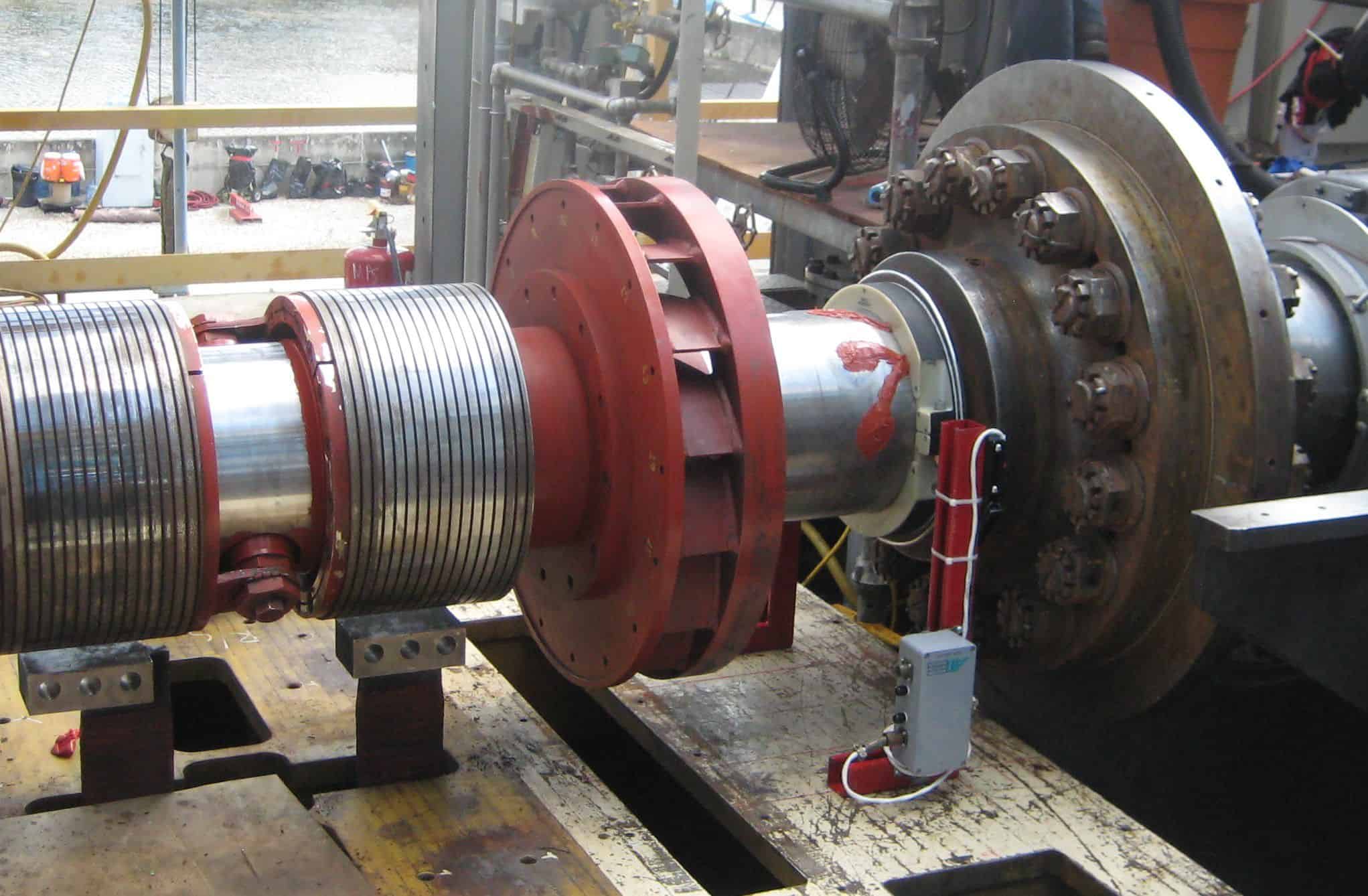

The friction caused by light rubbing on a rotor gives rise to localized heating (a so-called rotor “hot spot”) that is not uniformly distributed around the shaft circumfer- ence. This causes the shaft to expand longitudinally in a non-uniform manner, resulting in a bow (Figure 1).

While one might reasonably conclude that the ensuing shaft bow acts as a positive feedback mechanism, causing the rotor to rub even more, heat up even more, and subsequently bow even more, there is actually another mechanism at work in the case of light rubbing that counteracts this. In practice, the conditions that gave rise to the initial rub are frequently related to loading conditions, such as partial load operation, transient changes in load, or operation at higher-than-normal capacities.

Resulting Thermal Distortions

As a subsequent result of the loading, thermal distortion occurs in the machine and a rub ensues. However, as the load changes or the machine assumes thermal equilibrium in the new load condition, clearances open, and the rub stops. The rotor hot spot then cools, the bow relaxes, and the vibration decreases.

When the load changes again, a rub is initiated and the cycle repeats itself. In such situations, the amplitude trend will exhibit a cyclic increasing/decreasing behavior.

If the rub initiating mechanism is somewhat periodic, as in a load change that occurs at regular intervals, the periodicity in the amplitude trend may be regular as well. In cases where the initiating mechanism is not periodic, the amplitude trend will show variations, but there will be

Turbomachinery Multivariate Trend Plotting

Although rubbing conditions will sometimes be readily apparent from the shaft orbit plots, particularly for moderate to heavy streaks, the indications in the orbit from light rub conditions may be more subtle. Other plot types are thus useful.

A multivariable trend plot that allows the diagnostician to review vibration amplitude and load conditions simultaneously can be particularly helpful when it is suspected that a rub is occurring and is being initiated by load conditions.

Correlations between amplitude (and phase) changes and load changes can be easily observed using this plot type. If an increase in vibration is always accompanied by a transient change in load conditions, or occurs only when the machine is in certain load conditions (such as partial load), a light rub and corresponding thermal bow is a strong possibility.

As light streaks (or “rubs”) are a non-linear response mechanism, it is important to note that changes in phase and amplitude may not be repeatable from one cycle of the oscillation to the next.

The rub may be more severe, less severe, or absent entirely—as can be the case when the rub has sufficiently eroded the contacting locations to permanently alter clearances. Nor will the peaks and valleys of the amplitude trends be perfectly periodic, even if the initiating conditions (such as load changes) are themselves ideally periodic.

Turbomachinery Exploration 2 – The Morton Effect (Journal Thermal Gradients)

An alternate phenomenon can occur in rotating machinery and give data similar to that resulting from a light rub. Inspection of the machinery affected by this condition will show that no rub is in fact occurring.

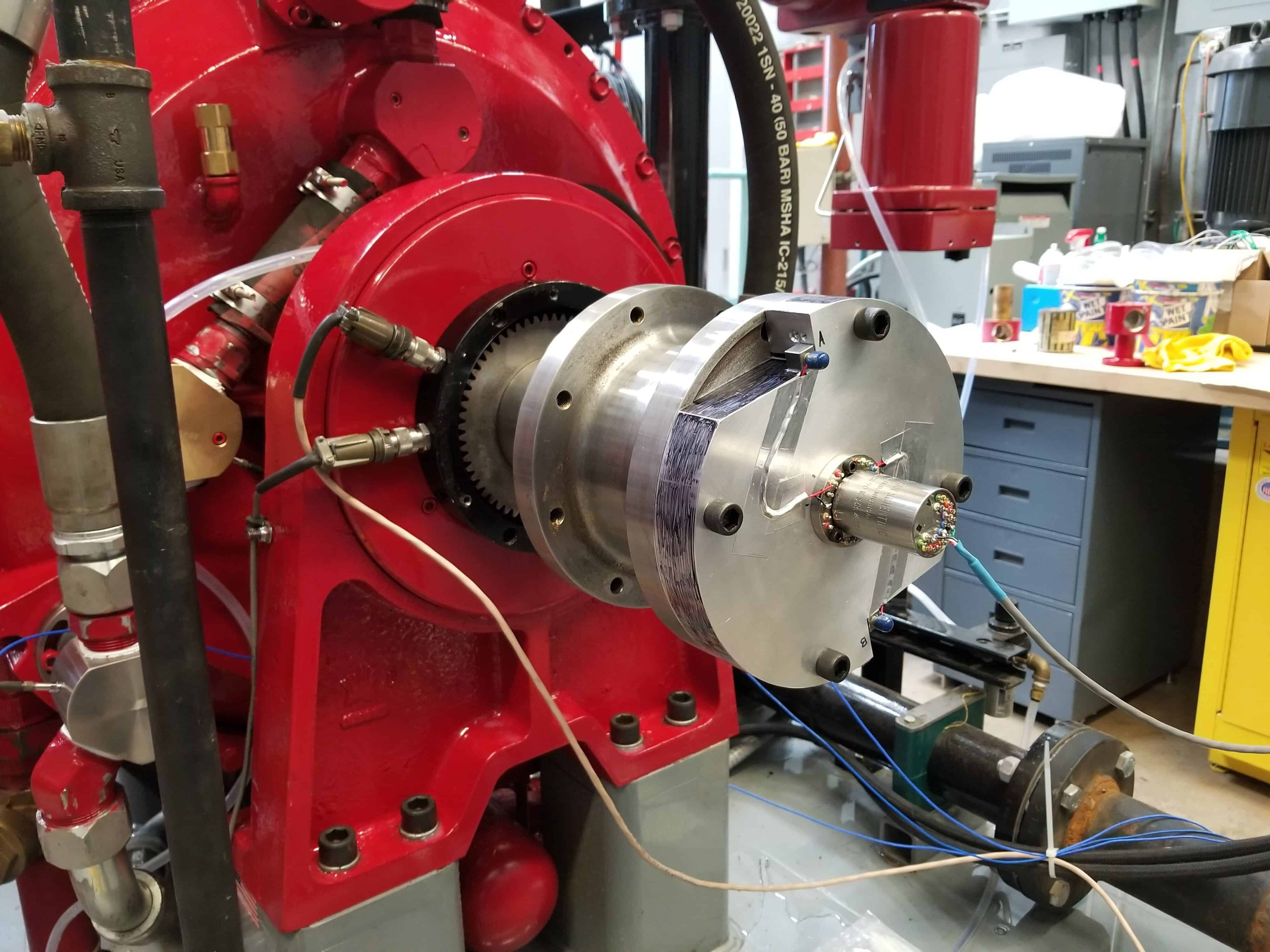

Instead, it has been postulated that temperature gradients (“hot spots”) occur on the shaft’s journal surface as the result of high viscous shear stress in the bearing lubricant. Consequently, the shaft bows just as if a hot spot occurred from a rub, and a very similar vibration response is observed.

Morton Effect in Turbomachinery Blades was first described in a 1994 paper by P.S. Keogh and P.G. Morton, now known as the “Morton Effect”, the condition occurs only under very specific conditions; in particular, on machines incorporating an overhung rotor design and which are heavily loaded.

In this article, only a brief overview of the so-called Morton Effect is provided so the reader can be familiar with the phenomenon should it be encountered in practice. The reader is strongly encouraged to obtain additional information on the Morton Effect and its underlying hypotheses using the references at the end of this article.

In addition, it is assumed that the dominant force acting on the machine is residual unbalance, and that the bearing stiffness is symmetrical about the centerline. This results in predominantly synchronous (1X) vibration with a largely circular orbit as the shaft vibrates within its bearing clearance.

Vibration of this form orients the rotor surface in the same position each time it rotates as long as loading and speed remain constant. This means that the same segment of the rotor’s circumference will always be subject to the mini- mum clearance while another segment of the rotor’s circumference will always be subject to the maximum clearance.

Although this condition creates a thermal gradient instead of a uniform heat distribution about the rotor’s circumference, unless the shear stresses are suitably large, the gradient will not be large enough to result in a shaft bow.

However, when the shear stresses are sufficiently large, the heating effect is appreciable and the shaft bows, just as if a rub was occurring at the location of minimum oil film thick- ness. As a result, the 1X vibration amplitude increases.

As the effect (temperature spot on the shaft) of this mechanism is quite similar to that of a light rub, it is not surprising that the vibration response may be quite similar as well.

However, as the Morton Effect occurs inside the bearing area where lubricant is present to provide cooling, the thermal rate of change tends to be more linear than that which occurs under true rub conditions.

Repeatable Vibration Patterns for Turbomachinery

As such, the vibration pattern is more repeatable from cycle to cycle and typically results in a polar plot with one of two distinct patterns:

1. Reiterative Loops

When the machine is under highly steady-state conditions without even minor variations in speed or load, the shaft attitude angle (i.e., location of the shaft on the supporting oil-film wedge in the bearing) remains highly steady as well.

Consequently, the “hot spot” on the shaft remains in the same location. As the machine under- goes its cyclic changes in amplitude and phase due to the repetitions of the shaft bowing and then relaxing, the stationery location of the hot spot results in changes in amplitude and phase that are so repeatable as to trace nearly the same pattern on the polar plot from one cycle to the next. For practical approaches, compare this response with the non-linearity (non-repeatability) of the response for an actual light rub condition.

2. Corkscrew Vibration

When the machine is experiencing small fluctuations in speed and/or load, the shaft attitude angle will experience small changes as well, causing the shaft hot spot to shift slightly.

This moving hot spot gives rise to spiral pattern in the polar plot as the shaft bows and relaxes cyclically. However, with the machine undergoing slight changes in speed/load. Now, the loops no longer exactly retrace themselves, but instead appear as expanding/contracting spirals.

Although the Morton Effect is far less common than light rubbing in machinery, there are certain indications that can lead the diagnostician to suspect this mechanism when other, more common, malfunctions have been ruled out:

- When the machine under investigation incorporates an overhung design and is heavily loaded.

- When visual inspection of the machine gives no evidence of a rub.

- When the 1X amplitude and phase variations appear to be quite repeatable and smooth from one cycle to the next

- When condition is far more repeatable than would be expected from either as re-traced loops or as spirals.

- When changes in the lube oil temperature affect the cyclic vibration periodicity and amplitude.

Conclusions | Morton Effect in Turbomachinery Blades

Light streaks are commonly encountered in rotating machinery and often give rise to a distinct, cyclical pattern in amplitude and phase trend plots, as well as polar plots. Shaft orbit plots are likewise valuable as they may give direct evidence of more pronounced streaks, observable as flat spots where motion is constrained or “bumps” where the shaft

actually bounces against a stationery surface such as a seal. The Morton Effect yields data similar to a rub because the underlying mechanism (localized heating) is the same.

However, in the case of a rub, the heating occurs due to mechanical friction as rotating and statio- nery parts contact one another, while in the case of the Morton Effect, the heating occurs as the result of excessive shear stresses in the lubricant. Uniting each of these principles, the factors point strongly towards the Morton Effect as the underlying cause of the elevated vibration levels.

This engineering edu-blog has hoped to produce an introductory overview of the Morton Effect, along with showcasing the ways in which polar plots may be used to differentiate this phenomenon from that of a legitimate rub or streaked condition.

Related Mechanical Testing Services Offered

Campbell Testing

Measuring the natural frequencies and mode shapes of rotating turbine blade (bucket) rows.

Torsional Vibration

Determine the natural frequencies and mode shapes of a rotor train as it twists about the axis of rotation.

Vibration Diagnostics

Identify the root cause of noise and vibration problems in machinery via ODS, spectral, order tracking or joint time frequency analysis.