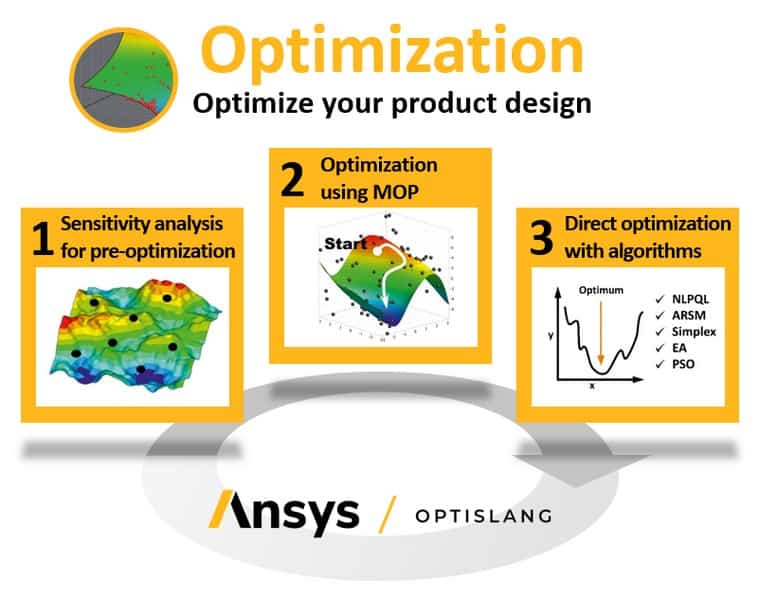

To execute parametric studies and optimize engineering designs, automate your simulation toolchains, using state-of-the-art optimization techniques.

Ansys optiSLang is a cutting-edge, constantly growing solution to the issues of CAE-based Robust Design Optimization (RDO).

Its vanguard algorithms swiftly and automatically find the most resilient design configuration, obviating the time-consuming, human process that was previously required to define RDO.

You’ll make better decisions faster with optiSLang as your process integration and design optimization solution.

Determine the best and most robust design configuration by using interactive wizards and automate the design process. With design optimization software, you can gain a deeper understanding of your design and make better judgments with less work thanks to cutting-edge algorithms for design exploration, optimization process, robustness, and reliability analysis.

All turbomachinery designs need to be optimized for efficiency

Evaluate & Validate Automotive Controller Software Functions

Increase Product Performance

Improve Product Performance by Pushing the Boundaries

Precise Simulation for Power Transmission

Supporting Video Content: