Designing the Aerospace Components of Tomorrow

Aerospace manufacturers must meet increasingly complicated demands from OEMs and regulators: lighter parts, faster design cycles, lower emissions, and zero compromise on safety. With simulation, suppliers can validate component designs early, ensure compliance with aerospace standards, and optimize for performance under extreme operating conditions. Simulation enables manufacturers to stay competitive while supporting the industry’s sustainability goals.

The future of aerospace manufacturing lies in using simulation to perfect every detail of your design. Ready to build lighter, stronger, and safer components, faster than ever? Let’s talk about how simulation can streamline your process and get your parts certified with confidence.

New Challenges for Aerospace Manufacturers

To remain competitive in a rapidly evolving market, aerospace suppliers must reduce development cycle times, minimize material waste, and prove compliance before the first part is even produced. With OEMs prioritizing sustainability and performance, every component must be lighter, stronger, and smarter. Simulation helps manufacturers:

- Digitally prototype and test complex geometries

- Validate materials for temperature, vibration, and corrosion resistance

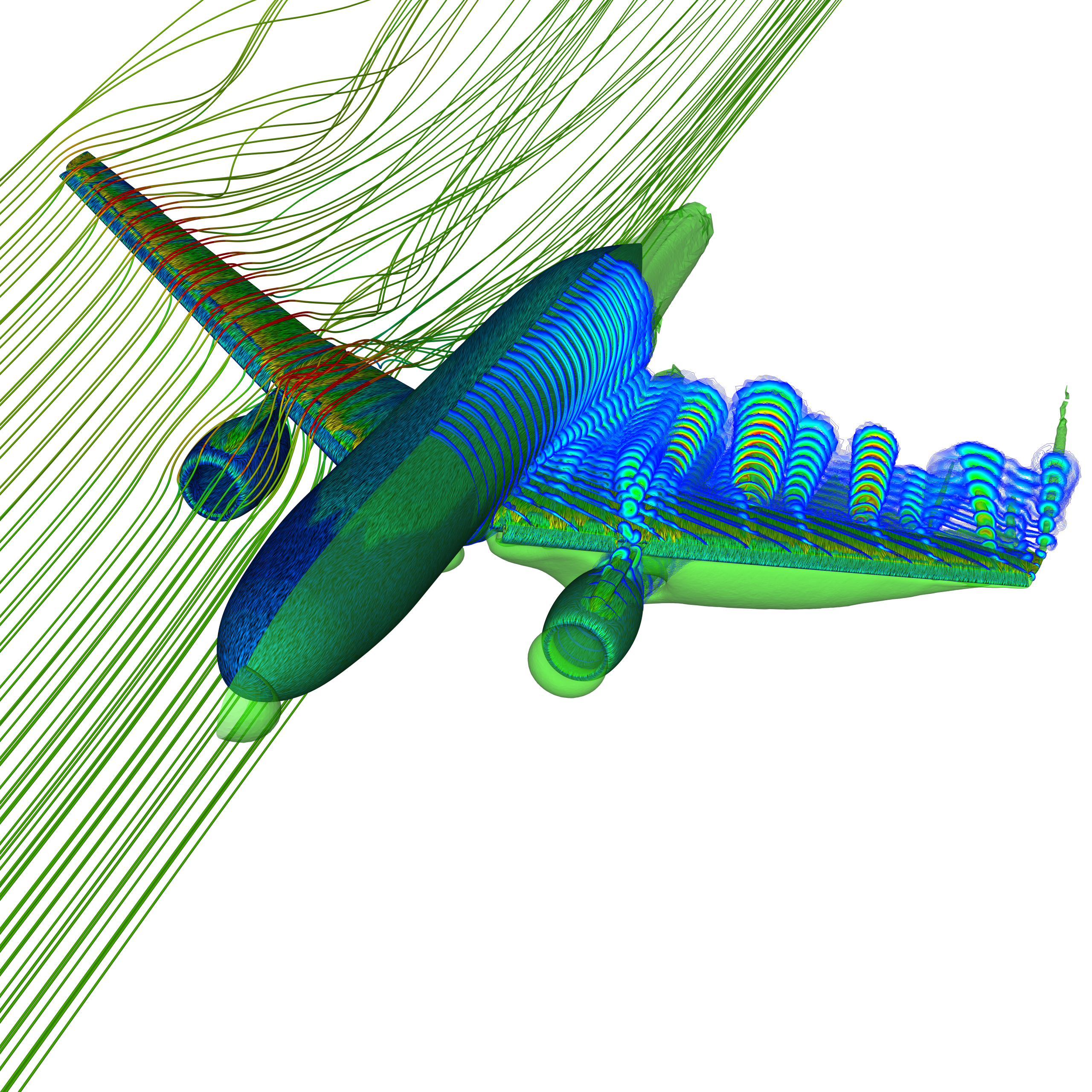

- Optimize designs for lightweighting and fuel efficiency

- Meet performance requirements under mission-critical load cases

Request a Consultation

Sustainability in Parts Manufacturing

Simulation plays a crucial role in supporting sustainability initiatives across the aerospace supply chain. By simulating materials, structural integrity, and functional performance at early stages, manufacturers can:

- Reduce the need for physical prototypes and rework

- Lower material waste through optimized geometries

- Improve energy efficiency of aircraft through lightweight designs

- Support OEM environmental benchmarks and emissions targets

Navigating Aerospace Certification Requirements

Certification is one of the most demanding and costly aspects of aerospace parts manufacturing. Simulation accelerates validation processes, offering clear documentation for certifying bodies while identifying issues before physical testing. Simulation supports:

- Fatigue and durability testing

- Static and dynamic load case simulation

- Safety-critical performance validation

- Environmental compliance (thermal, EMI, noise, emissions, etc.)

Material Selection and Advanced Manufacturing Techniques

Modern aerospace production depends on choosing the right materials and techniques, from additive manufacturing to composite layups. Simulation enables manufacturers to:

- Evaluate thermal, structural, and chemical performance of new materials (Granta)

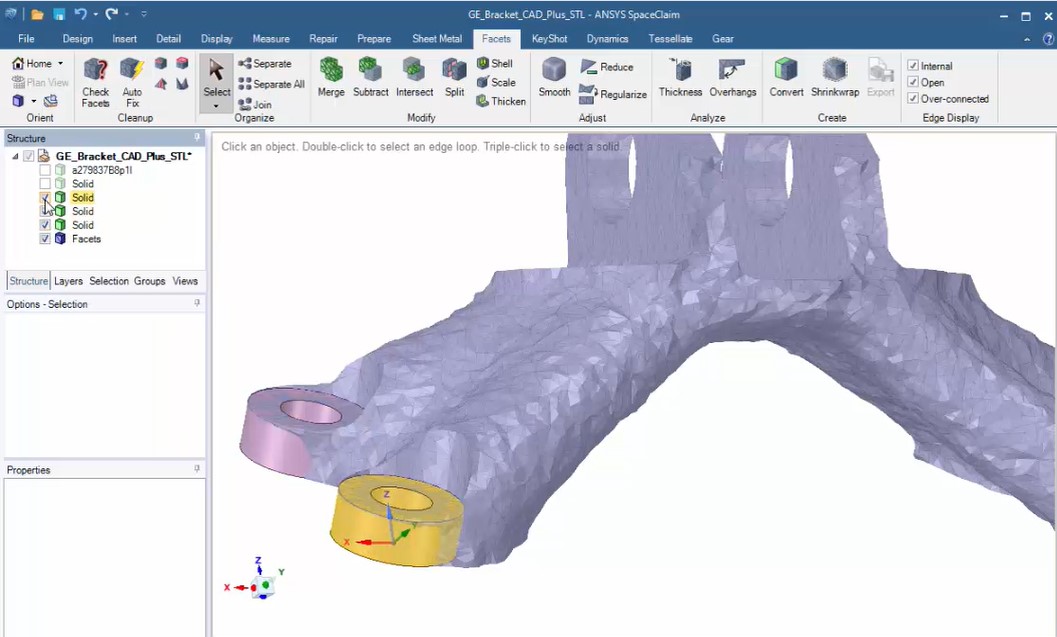

- Simulate additive manufacturing processes and built-in residual stress/warping from such processes

- Optimize fiber orientation and laminate stacking for composites

- Ensure part performance in fluctuating temperature and pressure environments

Supporting OEMs with Predictive Performance Insights

As OEMs explore electric and hydrogen propulsion systems, the demands to accommodate these technologies on parts suppliers are increasing. Simulation gives manufacturers the tools to stay at the forefront:

- Model component performance within propulsion or control subsystems

- Anticipate multiphysics interactions before integration

- Validate compatibility with high-voltage, high-temperature environments

Simulation Tools for Aerospace Parts Engineering

SimuTech Group helps parts manufacturers adopt advanced digital engineering tools from Ansys, including:

- Mechanical – Stress, fatigue, vibration analysis

- Granta – Materials selection and sustainability insights

- Additive Suite – Additive manufacturing process simulation, print design, and validation

- Fluent & Icepak – Fluid dynamics and thermal management

- HFSS, SIwave & EMC Plus – Electromagnetic compliance and EMI shielding

Your Aerospace Parts: Certified Faster, Stronger, and Smarter

With decades of experience helping aerospace suppliers deploy simulation-driven design and validation, SimuTech Group ensures your parts meet the highest standards for performance and compliance. We support your teams with software, training, and expert guidance to accelerate innovation and certification.

Get your aerospace components flight-ready with simulation. Let’s explore how to strengthen your parts manufacturing process today!

Other Aerospace Industry Applications

We’re Here to Help

Our team of experienced engineers can assist you at any step of your process.