Ansys Thermal Desktop

Experience unparalleled precision in thermal and fluids simulation with Ansys Thermal Desktop, the ultimate tool for transforming your design process from early evaluation to rapid, system-level problem-solving.

Experience unparalleled precision in thermal and fluids simulation with Ansys Thermal Desktop, the ultimate tool for transforming your design process from early evaluation to rapid, system-level problem-solving.

Ansys Thermal Desktop is a general-purpose thermal and fluids simulation tool for heat transfer, thermal radiation, environmental heating, and fluid flow design. It quickly solves component to system-level thermal and fluids problems, allowing for early design evaluation and rapid design changes.

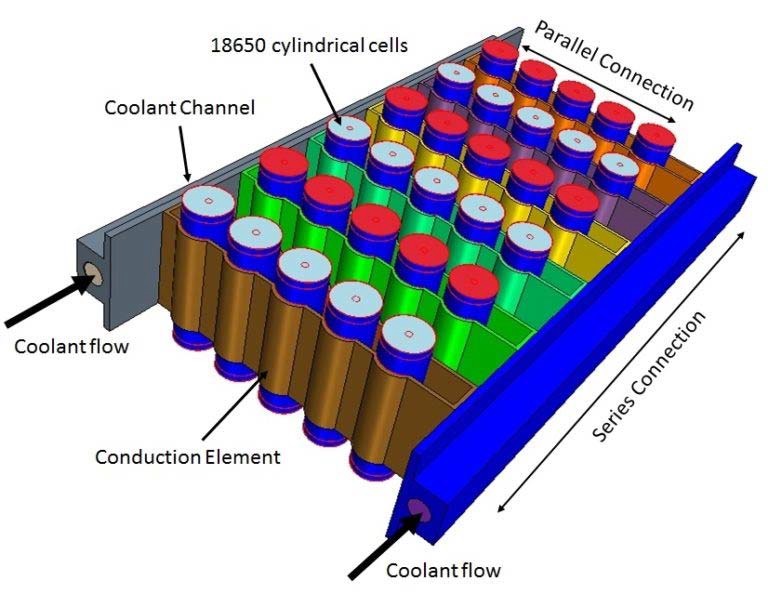

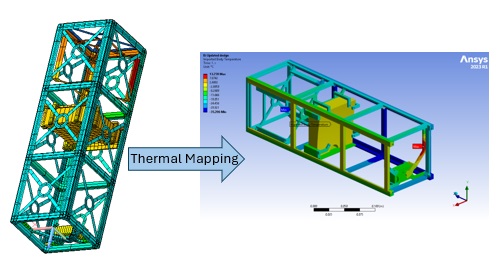

With Thermal Desktop, users across a range of industries can build virtual prototypes to design more robust products, ranging from automotive components to energy storage systems to manned spacecraft.

Ansys Thermal Desktop is a standout solution, offering a unique blend of capabilities that enable concurrent engineering for thermal and fluid analysts. It provides a comprehensive platform for CAD-based geometry, including seamless data exchange with structural codes, all while maintaining traditional thermal modeling practices.

With Thermal Desktop, you’ll gain access to a suite of comprehensive functionalities, including:

Ansys Thermal Desktop’s radiation solver is a powerful tool that simplifies the complex task of defining the radiation environment for thermal analysis. It can model crucial radiation effects, including solar rays, using Orbits. These Orbits define the appropriate diffuse and direct solar, albedo, and ground IR heating for various scenarios, from objects in a window to ships, aircraft, spacecraft, and even rovers on distant planets. In addition, Thermal Desktop is equipped with advanced capabilities to handle moving geometry. Its fully user-definable Trackers enable designated parts of the model geometry to track the sun, nadir, or any star. These robust radiation solver features make it an invaluable asset for thermal simulation.

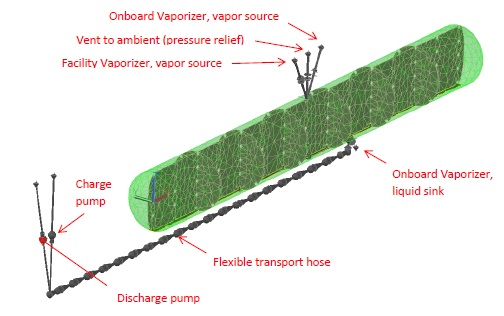

Leverage Ansys Thermal Desktop to model piping systems, heat transfer equipment and power cycles, tanks and vessels, and heat pipes. Thermal Desktop can also model single- or two-phase fluid systems, compressible and incompressible fluids, and fluid mixtures. Possible applications include custom control systems, turbomachinery, chemically reacting flows, complex vessels with many ports and piping penetrations, and capillary and thermosiphon systems.

As a generalized pipe flow software tool, Thermal Desktop captures the pressure drops in a piping network due to bends, valves, tees, changes in flow area, and more. As a full thermohydraulic software tool it considers the acceleration terms associated with axial variations in velocity due to density, side flow, or the transient storage and release of mass in compressible tanks in addition to phase change associated with evaporation and condensation. Combining these pipe flow capabilities with geometric ports provides enhanced modeling of fluid flow entering and leaving complex tanks and vessels.

Ansys Thermal Desktop can leverage curved elements to model complex phenomena on solar collectors with complex shapes. Gain valuable insights into the behavior of solar radiation, heat transfer, and fluid dynamics within collector and concentrator systems, aiding in identifying and mitigating potential issues such as overheating, shading, or optical losses.

Generic movement of collectors and concentrators can be accomplished using Assemblies, which allow any geometry part to rotate and/or translate in unlimited nested configurations. Because they are general-purpose, Assemblies can be used to model anything from deploying a multi-jointed antenna to opening a furnace door.

Ansys Thermal Desktop is not just software; it’s a powerful solution for electronic thermal design and prototyping. Its simulations offer predictive insights into temperature distributions, empowering proactive cooling system design to prevent overheating and component failure. Furthermore, they facilitate the optimization of cooling techniques and fine-tuning of parameters such as airflow and heat sink design, leading to maximum efficiency.

Thermal Desktop, having been widely used in the aerospace industry for decades, differentiates itself from other network style solvers by expanding the applicability of the code to electronics with convective environments, liquid cooling, and two-phase cooling loops (including refrigeration, thermosiphons, and immersion cooling). The geometric interface provides 3D CAD methods for simulating air cooling and thermal behavior of electronic enclosures, PC boards, heat sinks, and electronic racks.

Using Ansys Thermal Desktop, you can accelerate the design process, minimize development costs, and enhance the reliability and safety of fuel tank systems. Thermal Desktop can predict and optimize factors such as fuel sloshing dynamics, pressure distribution, and structural integrity, reducing the need for costly physical prototypes.

Simulations allow for the accurate modeling and prediction of temperature distributions within a tank, especially in scenarios where stratification occurs, with layers of different temperatures forming within the tank. Understanding these temperature gradients is crucial for optimizing the performance of systems utilizing thermally stratified tanks, such as solar thermal storage or HVAC systems.

Thermal Desktop can be used to evaluate different tank geometries, insulation materials, and operating conditions to maximize thermal efficiency and minimize energy losses. By simulating various scenarios, engineers can identify potential issues such as thermal mixing, heat loss, or stratification imbalance, enabling proactive design adjustments to enhance system performance and reliability.

Heat pipe routines built into Ansys Thermal Desktop provide fast system-level solutions to modeling heat pipes when a full two-phase solution is not required. Both constant conductance (CCHP, also called FCHP), with or without non-condensable gas (NCG), and variable conductance (VCHP) pipes can easily be simulated, using either 1D or 2D thermal models (axial, axial and circumferential, rectangular). These routines were written specifically to co-solve wall temperatures and gas-front locations, resulting in a more robust tool that is capable of predicting QLeff (power-length product). In addition, fast and easy geometric model generation can include bonding or contact to thermal surfaces and solids and even to other heat pipes.

The methods for modeling loop heat pipes (LHPs) and capillary pumped loops (CPLs) are very different from those used to model heat pipes. Unlike a heat pipe, self-pumping loops require full thermohydraulic modeling of the fluid and the thermal-structural environment. In addition to supporting the modeling of single-phase pumped loops, Thermal Desktop has several features which make it uniquely capable of modeling two-phase pumped loops and capillary pumped loops. Using Thermal Desktop, you can capture everything from the system-level effects of the LHP all the way down to detailed thermodynamic and hydrodynamic transient events such as LHP start-up, compensation chamber (reservoir) quenching, partially primed wicks, and pressure and flow oscillations.

Tracking the energy of a phase change can be difficult if your software isn’t designed to handle it. Ansys Thermal Desktop provides a user-friendly interface for defining the thermophysical properties of phase changing materials and its solver accurately models this energy. This methodology can be applied to something as simple as melting ice, but specific phase-change materials (PCMs) are designed to be used across many industries such as solar thermal storage, solar power plants, medical devices, electronics, spacecraft, and food storage. The intent is to absorb or release significant amounts of energy while maintaining a constant temperature.

With the help of Thermal Desktop, you can evaluate the performance of PCM configurations under different operating conditions and identify potential issues such as thermal stratification, PCM degradation, or leakage, enabling proactive design adjustments to enhance reliability and durability.

Thermoelectric couples are solid-state devices capable of generating electrical power from a temperature gradient, known as the Seebeck effect, or converting electrical energy into a temperature gradient, known as the Peltier effect. To assist the thermal designer in modeling these Peltier devices (thermoelectric generators (TEGs) or coolers (TECs)), Ansys Thermal Desktop provides built-in routines for modeling devices using either standard Bismuth Telluride properties or alternative semiconductor materials. The TEC and TEG tools allow the designer to model single-stage or multi-stage devices and calculate valuable sizing information regarding thermoelectric performance.

Thermal Desktop’s unique system-level approach for modeling single and multi-stage coolers captures the device’s system-level performance along with the device’s effect on the host system. Detailed geometric modeling of all the individual elements (P-N couples) is not required resulting in fast run times. Modeling options are available to perform parametric modeling, sensitivity studies, and design optimization.

Ansys’ most powerful computational fluid dynamics tool, Fluent, includes physical modeling capabilities to deliver fast, accurate results across the widest range of CFD and multiphysics applications.

Ansys CFX is a high-performance CFD tool that delivers reliable, fast, and accurate solutions for a wide range of applications, including leading capabilities for rotating machinery.

Ansys EnSight is the market leader for data visualization. Its post-processing tool includes models with more than hundreds of millions of cells, providing engineers with insights unavailable elsewhere.

Ansys Polyflow provides advanced fluid dynamics technology for companies in the polymer, glass, metals, and cement processing industries.

Ansys TurboGrid complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Ansys Thermal Desktop takes a systems level approach to help solve complex thermal and fluid flow problems.

Ansys BladeModeler complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Ansys Vista TF complements rotating machinery simulation by enabling engineers to quickly develop blade geometries that achieve desired performance objectives.