Simulation-Driven Innovation for Hybrid, Electric, and Hydrogen Propulsion

Propulsion innovation is at the heart of sustainable aviation. But developing viable alternatives to traditional jet engines, especially for hybrid-electric, all-electric, and hydrogen-powered aircraft, requires mastering a host of complex design, integration, and safety challenges. Simulation provides a competitive edge by helping you optimize propulsion architectures, manage multiphysics interactions, and validate safety-critical systems across every stage of development.

The future of flight depends on propulsion systems that are cleaner, quieter, and more efficient. Curious how simulation can help you fast-track development while meeting safety and performance goals? Let’s start a conversation.

New Propulsion Architectures, New Engineering Demands

Modern aerospace propulsion systems are evolving rapidly. Startups and OEMs alike are reimagining how aircraft of all types generate thrust, using everything from distributed electric propulsion to hydrogen fuel cells. These systems promise lower emissions and better efficiency. But they also introduce some major engineering hurdles.

Simulation helps aviation teams meet these challenges head-on, accelerating the development of next-gen propulsion systems while reducing cost, time, and risk.

Request a Consultation

Hybrid-Electric Propulsion

Hybrid systems combine electric and combustion technologies to increase range and reduce fuel usage. These architectures are likely to see earlier adoption, especially in regional aircraft applications. Simulation enables:

- Electric drivetrain design and systems integration

- Control software safety checks and model-based development (SCADE)

- Power electronics and inverter optimization

- Mechanical load balancing and vibration analysis

Electric Propulsion Systems

Electric propulsion replaces or augments traditional combustion engines with electric motors powered by batteries or fuel cells. While ideal for short-haul and eVTOL aircraft, these systems must overcome limitations in power density, thermal behavior, and electromagnetic interference (EMI). Simulation supports:

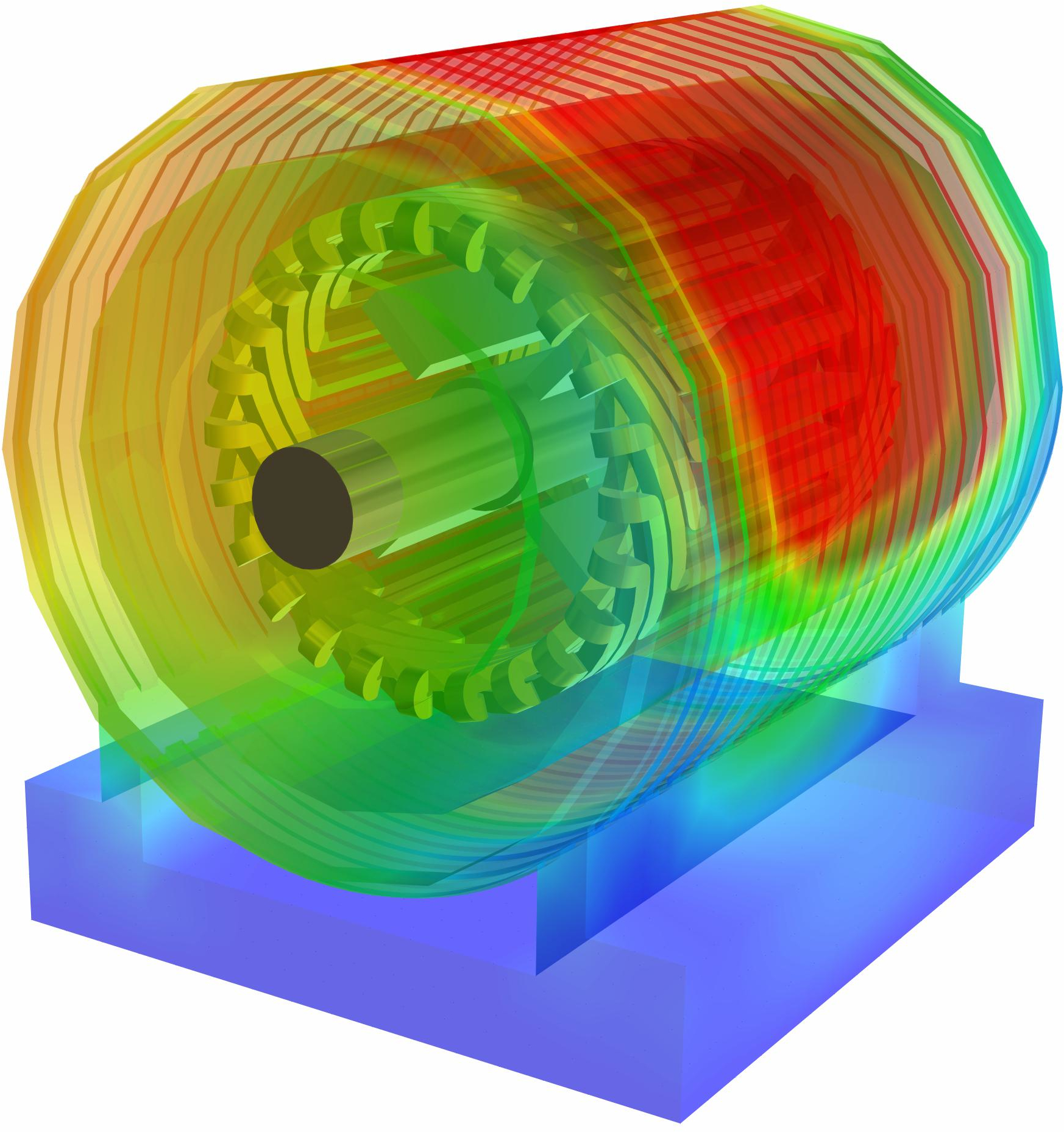

- Motor and generator design with multiphysics analysis (Maxwell, Motor-CAD)

- EMI/EMC prediction and thermal management

- Battery integration, structural stress testing, and operational reliability

- Embedded software verification and validation

Hydrogen Propulsion Systems

Hydrogen offers zero-carbon emissions and higher energy per unit mass than traditional fuel, but it comes with very significant design and safety challenges. From cryogenic storage to combustion stability, hydrogen propulsion is only viable with advanced simulation tools. Simulation delivers:

- Cryogenic storage system analysis (Granta, Fluent)

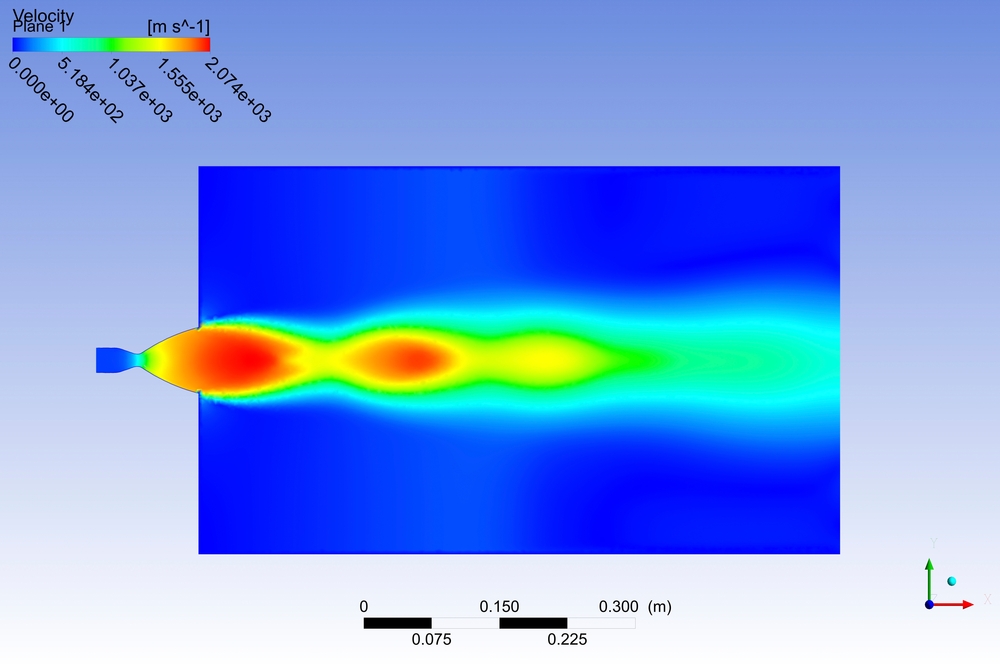

- Hydrogen combustion modeling and flashback prediction (Chemkin)

- Fuel cell electrochemistry performance and thermal dynamics

- Structural resilience under vibration, temperature, and pressure extremes

Tools of the Trade: Simulation Software for Propulsion Innovation

SimuTech Group supports aerospace propulsion systems development with the full Ansys toolset:

- Maxwell, Motor-CAD, SIwave – Electric motor design and EMI analysis of IC/PCB packages

- Fluent, Chemkin – Fluid dynamics and combustion modeling

- Granta – Material selection and thermal resilience

- SCADE – Embedded control software development

- Mechanical, Icepak – Structural and thermal systems analysis

- medini – Functional safety analysis and compliance

System-Level Integration and Certification Readiness

Across all propulsion types, aerospace teams must validate how systems interact under real-world conditions. Simulation helps engineers map out complex interdependencies, reduce the need for physical prototypes, and meet rigorous aerospace propulsion systems certification requirements. Use simulation to:

- Model dynamic system interactions and failure modes

- Validate safety-critical software and hardware performance

- Simulate power duty cycles and evaluate EMI compliance

- Improve manufacturability and maintenance strategies

Why Partner with SimuTech Group?

With more than four decades of engineering simulation expertise and a deep understanding of aerospace propulsion systems and their requirements, SimuTech Group helps aviation manufacturers push boundaries of innovation with greater confidence. As North America’s largest Ansys partner, we provide software, training, consulting, and support through every stage of design and development.

Ready to accelerate your electric, hybrid, or hydrogen propulsion project? Schedule a consultation to discover how simulation can optimize your next-gen propulsion system.

Other Aerospace Industry Applications

We’re Here to Help

Our team of experienced engineers can assist you at any step of your process.