Background

Intelligent Engineering Limited (IE), has developed and patented the Sandwich Plate System (SPS), which integrates a steel-elastomer-steel composite structural laminate in place of conventional stiffened steel plates.

Sandwich Plate System Challenge

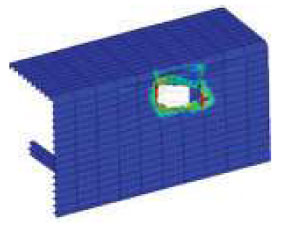

A study was commissioned to confirm the feasibility of installing an SPS-based fendering system to protect the side shell structure on an FPSO (Floating Production, Storage and Offloading) vessel in way of the boat loading area. The existing methodology was to generate cofferdams in the region of ship impact to protect the main hull. This is extremely costly and must be performed in dry dock thus taking the ship out of commission for an extended period and impacting revenue generation. The objective was, by using SPS, to meet the relevant requirements of IMO MARPOL Annex (ship impact) and eliminate the need to install cofferdams in this area, thus maximizing the dead weight capacity of the FPSO, minimizing conversion and life cycle costs of the vessel, reducing inspection and maintenance requirements and creating an inherently safer design both in terms of conclusion and operation.

Sandwich Plate System Solution

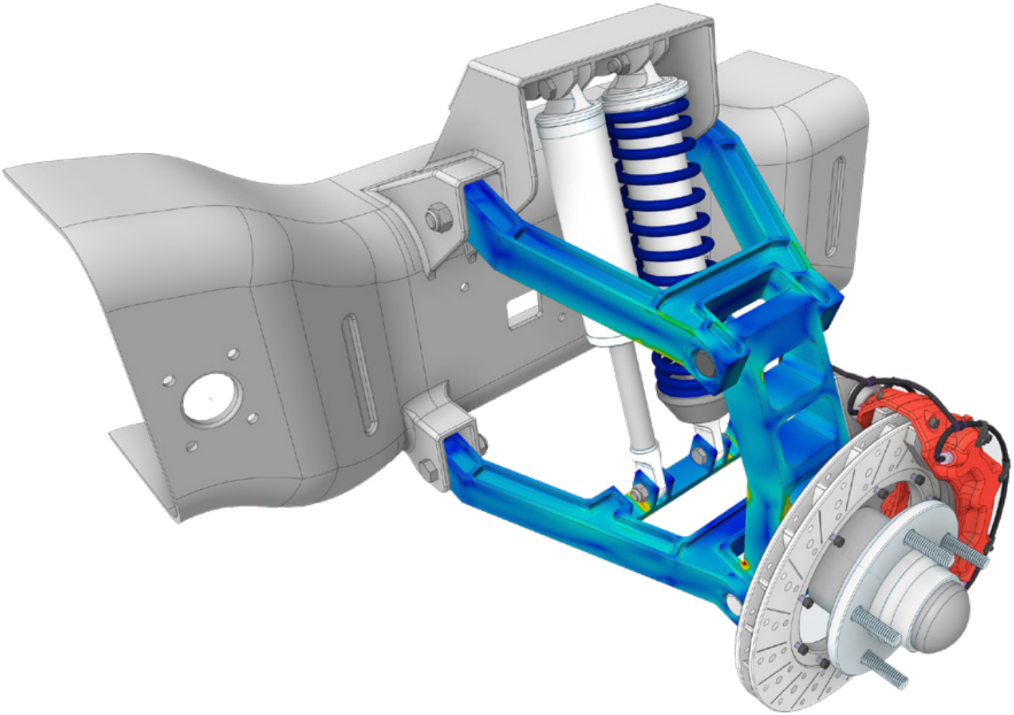

SimuTech Group performed the computer simulation of the ship’s collision. This involved the FEA modeling, analyses, and collection of the results. IECAD models were modified with Ansys Design Modeler. Ansys AI* Environment was used to generate the structured mesh. The dynamic simulation was solved with Ansys LS-Dyna. Some pre- and all post-processing operations were done with LS-PrePost. Numerical models were solved on SimuTech Group’s 12-CPU-32-GB-RAM SGI Altix system.

This simulation showed that SPS overlay provides more than three times the energy absorption capacity of the existing steel FPSO before rupture occur. The desired energy absorption response can be achieved by simply increasing the Overlay plate thickness to a reasonable upper limit. ASPS overlay can engage, more effectively, a larger area of the plate to absorb the impact energy. A specific SPS Overlay solution would provide close to 100%.

Additional Ansys Software Tips & Tricks Resources

-

- Analyzing normal and Tangential Elastic Foundations in Mechanical

- Why Meshing is Crucial for FEA Fluid Simulations Prior to Prototyping

- For support on Contained Fluid FEA Modeling with HSFLD242 Elements

- For Exporting a Deformed Geometry Shape Post-Analysis in Mechanical

- Moreover, for guidance Multi-Step Analyses in Mechanical

- For Retrieving Beam Reaction Force in a Random Vibration Analysis

- Deploying Ansys Macro Programming vis *USE Command in Mechanical

- For replicating Fatigue Models from Start to Finish in Mechanical

- In addition, setting up Acoustic Simulations of a Silencer

- For a step-by-step guide on 2D to 3D Submodeling in Mechanical

- For modeling Pipe16 Circumferential Stress in Mechanical

- For Support on performing ‘EKILL‘ in Workbench

- APDL Command Objects post-Spectral Analysis

- For Separating DB Database Files from RST Files

- Measuring Geometric Rotation in Mechanical WB

- Explicitly, CAD Geometry Deformation Plasticity

- Offsetting a Temperature Result to Degrees Absolute

- For general guidance on Ansys Post-Processing

- Finally, for basic Ansys Software Installation and License Manager Updates