Webinar Description | Benefits of Additive Manufacturing Software

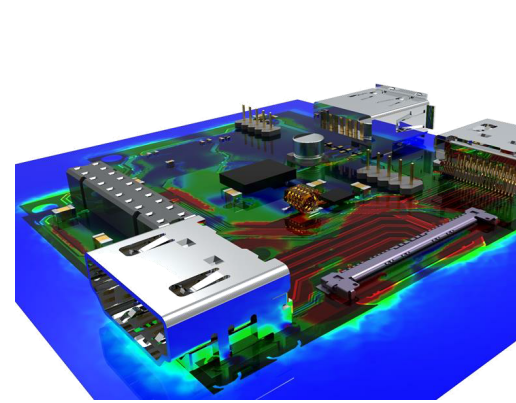

Ansys offers a complete simulation workflow for additive manufacturing (AM) that allows you to transition your R&D efforts for metal AM into a successful manufacturing operation. Additive manufacturing (3D printing) is a technology that produces three-dimensional parts layer by layer from a variety of materials.

It has been rapidly gaining popularity as a true manufacturing process in recent years. In the AM process, a digital data file is transmitted to a production machine, which ultimately translates an engineering design into a 3D-printed part.

Initially, AM was utilized as a rapid prototyping method — an accelerated method to create (mostly plastic) parts before manufacturing by well-accepted methodologies, such as injection molding, casting, forming, joining, etc.

Use Cases for Additive Manufacturing Push Past Prototyping

The value that additive manufacturing use cases provide within an organization, as opposed to the technology itself, is what defines them by definition. This value may manifest as increased operational effectiveness, the development of fresh goods and services, or even a transformation of the client experience.

Prototyping was the main use case for 3D printing in its early stages. Prototyping is still prevalent and always will be. However, more use cases are proliferating as 3D printing technology advance and become more affordable, as software advances, and as the variety of materials available expands.

These use cases include, among others, parts for new goods, parts for the aftermarket, jigs, fixtures, tools, molds, and clothing.

Accessories for New Products in Additive Manufacturing

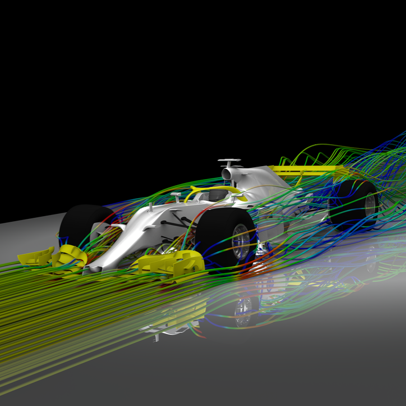

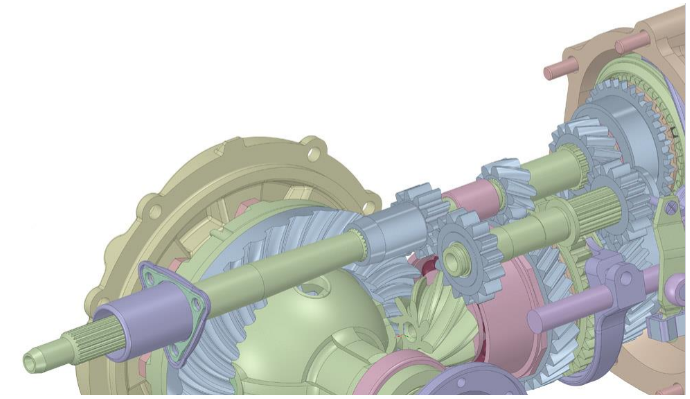

For the G2 RS engines, which are more effective, lighter, and stiffer, automotive manufacturers all around the world use 3D-printed aluminum pistons.

Advances in 3D printer technology, aluminum powder, and generative design software allowed for the creation of the superior product. The process of maximizing efficient geometries as part of a design scenario begins with automated computer simulations generated by the program.

By using laser metal fusion, the aluminum alloy is atomized into a thin powder and printed.

Aeronautical Systems by General Atomics | AM Software

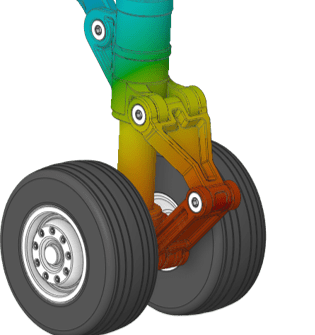

To print a National Advisory Committee for Aeronautics (NACA) inlet, General Atomics Aeronautical Systems has teamed up with GE additive, for example. This is simply where the industry is heading to maximize operational efficiency.

In addition, utilizing laser powder bed fusion methods, the part is printed. Additional potential materials for metal additive manufacturing that can be advantageous economically have also been found.

Tools, Jigs, Fixtures, and Molds in Additive Manufacturing (AM)

Important components of the manufacturing process include jigs, fixtures, and tooling.

A plant may be offline for a long time while awaiting repair if one of these breaks. International manufacturers are quickly integrating 3D printing into their production processes. They are no longer need to wait weeks for intricate parts or tooling.

They can now produce tools, fixtures, and manufacturing aids in-house quickly thanks to 3D printing, which has accelerated the introduction of new products and raised customer satisfaction.

The Healthcare Sector is Rapidly Advancing due to Medical Device Simulation

Applications for additive manufacturing include the production of hearing aids, splints, and 3D printed prosthetics.

Recently, implants that are visible inside the body have increased in frequency as bio-friendly materials and techniques develop.

To encourage better bone growth within the implant, international manufacturers of medical devices are increasingly integrating different Titanium alloy materials with generative design topology optimization tools (osseointegration).