Engineer a More Sustainable Future in Aviation

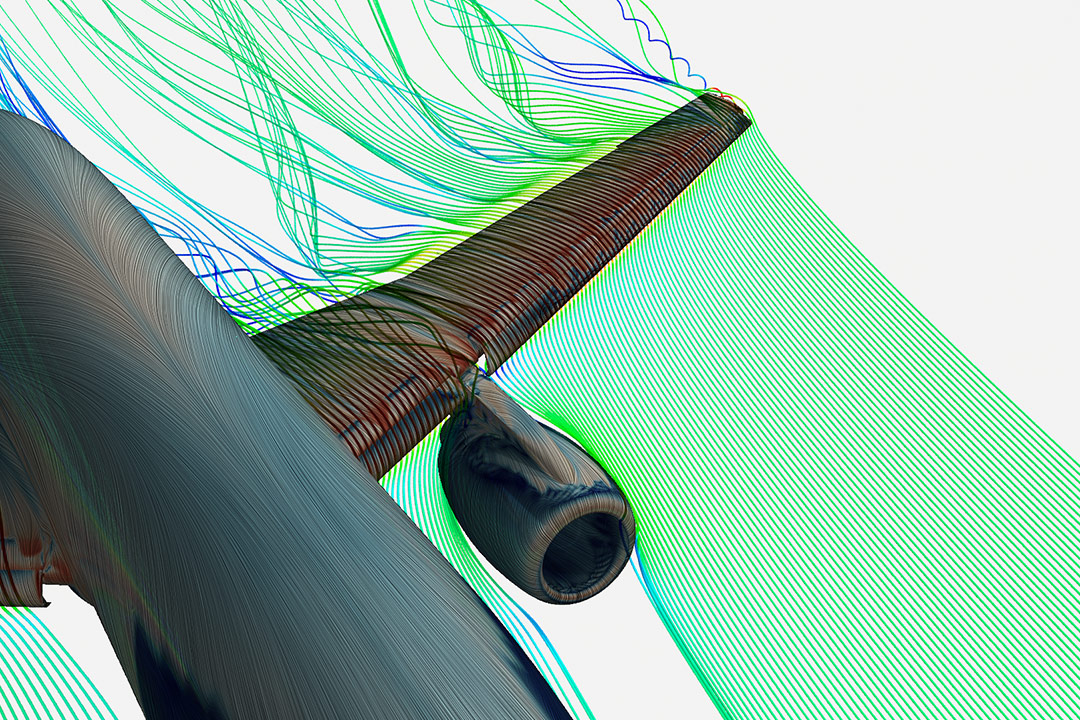

The future of flight depends on propulsion systems and materials that are lighter, cleaner, and more efficient. With air travel expected to nearly double by 2040, simulation is essential to meeting ambitious sustainability goals without compromising performance. SimuTech Group helps aerospace teams accelerate innovation, from hybrid-electric design and hydrogen fuel systems to smarter energy strategies that reduce emissions across operations.

Simulation is key to balancing sustainability with real-world performance. Let’s explore how our services and Ansys expertise can support your journey to net-zero, efficiently and confidently.

The Urgency of Sustainable Aviation

The environmental impact of aviation continues to be a focus across the globe. Despite accounting for a relatively small portion of total emissions, the sector’s high-altitude fuel burn has a disproportionate effect on climate change. And with the number of air travelers expected to climb to 7.8 billion by 2040, pressure is mounting from regulators, investors, and the flying public.

Simulation empowers aviation engineers to meet tightening emission regulations while also reducing noise pollution, fuel consumption, and material waste without compromising safety or performance.

Request a Consultation

Key Sustainability Drivers in Aviation

- Hybrid-Electric and All-Electric Propulsion: Electric propulsion systems reduce or eliminate direct emissions. Simulating drivetrain design, energy storage, and power electronics helps manufacturers reach targets faster.

- Hydrogen-Powered Aircraft: Hydrogen fuel cells and combustion systems promise zero-carbon emissions. Simulation helps engineers assess cryogenic storage and fuel cell performance in extreme conditions.

- Lightweight Materials and Aerodynamic Efficiency: From structural optimization to drag reduction, simulation accelerates lightweighting and design optimization.

- Lifecycle Efficiency and Certification Readiness: Simulation enables early tradeoff studies, predictive maintenance strategies, and compliance with certification and safety standards.

Real-World Innovations in Sustainable Aviation

OEMs and aerospace startups are already using simulation to power bold initiatives:

- eVTOL developers are building quiet, all-electric short-haul aircraft for urban mobility.

- Major airliner manufacturers are piloting hybrid-hydrogen engines that combine traditional turbines with hydrogen fuel cells.

Other manufacturers are optimizing electric propulsion architectures and power electronics to support hybrid aircraft development.

Simulation in Sustainable Aircraft Design

Digital engineering allows teams to virtually test, refine, and re-test every component of sustainable aircraft development, reducing reliance on expensive prototypes, wind tunnel testing, and other costly and time-consuming development processes.

Simulation tools enable:

- Multiphysics modeling for integrated systems (thermal, electromagnetic, structural)

- Trade-off analysis between weight, noise, fuel efficiency, and emissions

- Embedded software and safety systems validation

- Battery and fuel cell performance modeling

- Materials selection and optimization

Why Simulation is Essential for Aerospace Sustainability

The complexity of modern propulsion systems — particularly electric, hybrid-electric, and hydrogen configurations — demands a holistic approach to systems engineering. Without simulation, design teams face higher risks, longer timelines, and greater costs associated with reaching their sustainability in aviation goals.

With tools like multiphysics solvers, digital twins, and embedded software validation, engineers can:

- Reduce emissions and fuel burn across the entire lifecycle

- Meet evolving certification and compliance standards

- Minimize thermal risk and electromagnetic interference

- Design for manufacturability and maintenance

Simulation Software for Sustainable Aviation Engineering

SimuTech Group supports aerospace teams to achieve their sustainability in aviation goals with the full Ansys simulation suite, including:

- Fluent & Chemkin – Fluid dynamics and combustion

- Maxwell & SIwave – Electromagnetic performance and EMI/EMC prediction

- Motor-CAD – Electric machine design

- SCADE – Embedded software development

- Granta – Materials selection and sustainability

- Mechanical & Icepak – Structural analysis and thermal management

Partner with SimuTech Group to Achieve Sustainability in Aviation

SimuTech Group brings over 40 years of simulation experience to help aerospace companies transform their sustainability goals into engineering realities. As North America’s largest certified Ansys partner, we provide not only the software, but the consulting, training, and support to help your team reach certification faster and with less risk.

Let’s engineer a cleaner future together. Talk to our simulation experts to learn how SimuTech Group can accelerate your aerospace sustainability goals.

Other Aerospace Industry Applications

We’re Here to Help

Our team of experienced engineers can assist you at any step of your process.