Background | Mechanical Design Studio (MDS)

At Mechanical Design Studio (MDS), their art is seeing green, comfortable, elegant, and functional building systems made possible. This is the passion that drives their work.

Their team of mechanical consulting engineers offers expertise in heating, ventilation, and air conditioning (HVAC), plumbing, fire protection, and process piping – the central nervous system of any building. With certified Leadership in Energy and Environmental Design (LEED) professionals on staff, MDS is committed to sustainable design. Having been involved in many LEED projects, they have helped to ensure clients reach their LEED certification including gold and silver levels.

Challenge for Mechanical Design Studio (MDS)

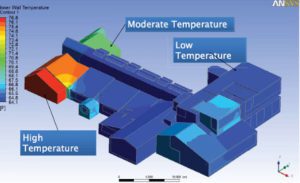

For one consulting project, MDS was tasked with resolving HVAC issues of an existing residential building. With the original HVAC design, it was thought that the always present natural wind flow would provide sufficient cooling for the interior of the house. However, the extensive number of windows in the building was thought to be causing uneven temperature distribution causing some unpleasant effects for the residents.

Solution for Mechanical Design Studio (MDS)

To get a better handle on the situation, MDS turned to SimuTech Group for a Computational Fluid Dynamics (CFD) model of the building and its HVAC system. The purpose of the CFD model was to provide thermal maps and velocity vectors of the air flow for the existing building interior as well as propose modification that added roof vents, providing a means of natural convective flow. In both cases, the loading consisted of solar radiation and wind conditions for a typical “warm day” scenario.

The various temperature maps and velocity vectors from the CFD results showed that the added roof vents provided: 1) better air flow, 2) more even temperature distribution and 3) sufficient cooling in the living quarters of the building’s interior thus ensuring a more pleasant living environment for the residents.

![]()

Additional Ansys Software Tips & Tricks Resources

-

- Analyzing normal and Tangential Elastic Foundations in Mechanical

- Why Meshing is Crucial for FEA Fluid Simulations Prior to Prototyping

- For support on Contained Fluid FEA Modeling with HSFLD242 Elements

- For Exporting a Deformed Geometry Shape Post-Analysis in Mechanical

- Moreover, for guidance Multi-Step Analyses in Mechanical

- For Retrieving Beam Reaction Force in a Random Vibration Analysis

- Deploying Ansys Macro Programming vis *USE Command in Mechanical

- For replicating Fatigue Models from Start to Finish in Mechanical

- In addition, setting up Acoustic Simulations of a Silencer

- For a step-by-step guide on 2D to 3D Submodeling in Mechanical

- For modeling Pipe16 Circumferential Stress in Mechanical

- For Support on performing ‘EKILL‘ in Workbench

- APDL Command Objects post-Spectral Analysis

- For Separating DB Database Files from RST Files

- Measuring Geometric Rotation in Mechanical WB

- Explicitly, CAD Geometry Deformation Plasticity

- Offsetting a Temperature Result to Degrees Absolute

- For general guidance on Ansys Post-Processing

- Finally, for basic Ansys Software Installation and License Manager Updates