High-Speed Connector Design | Ansys Webinar:

A technical look at the design and engineering considerations for high-speed connector design using engineering simulation software from Ansys Electronics.

It’s Not Just a Case of Joining Metal and Plastic

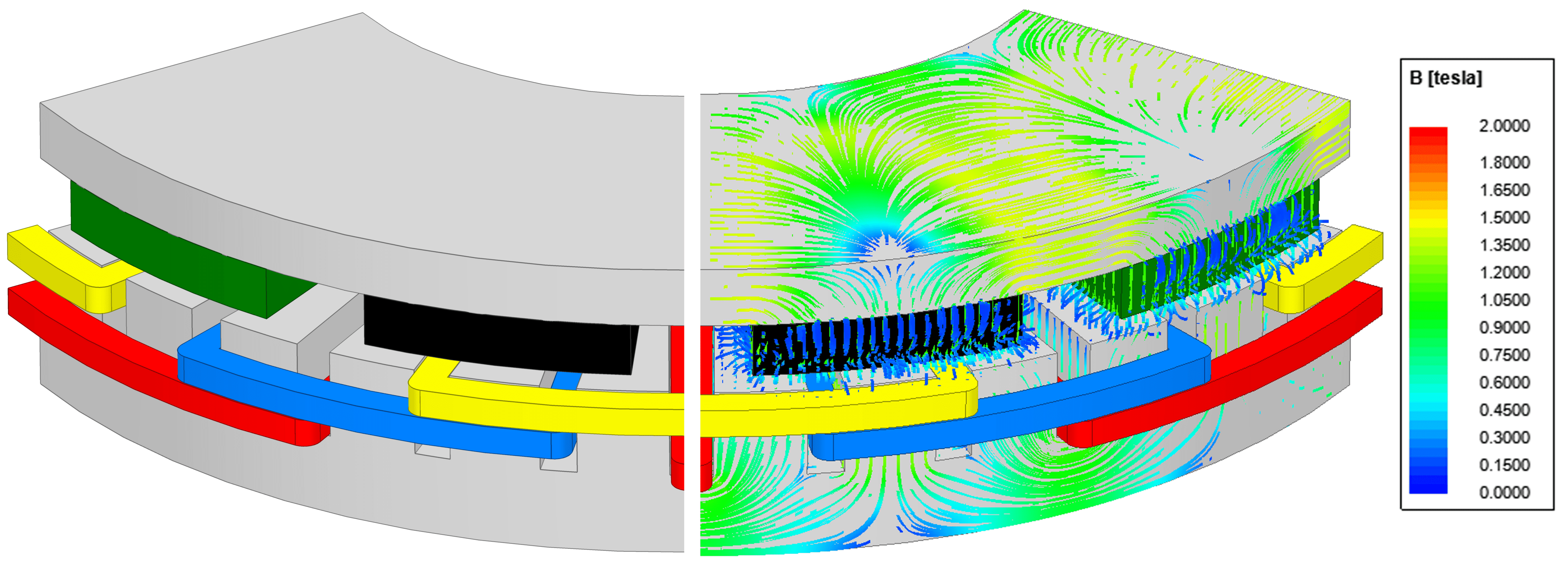

Signal transmission across PCBs in multi-boards is frequently done using high-speed connectors. In signal integrity and channel analysis of a system, investigation of their features is crucial. In this application note, a high-speed differential connector is modelled and 3D complete wave simulations of the connector are shown in a lab setting. Comparing laboratory experimentation reference measurement data with simulated connection properties.

Opposing Ideologies in High-Speed Connector Design

There are two competing concepts in the high-speed connector design field. For some people, a signal transmission can be created by simply joining parts of plastic and metal. This technique is pretty easy to follow.

On the other end of the spectrum, there is the notion that a reliable connector design necessitates a profound comprehension of electromagnetic theory—a knowledge that is only available to sorcerers and wizards. The truth is ambiguous, as it is with practically everything in life. Our team will make an effort to demystify several high-speed connector design principles in this on-demand webinar.

Specializing in High-Speed Connector Design

Companies wouldn’t have specialized teams solely for connector design if the design of high-speed connectors were straightforward. These teams are made up of signal integrity (SI), mechanical, and manufacturing engineers on the engineering side alone. If mechanical engineers discuss normal force or mating cycles, manufacturing engineers discuss tooling or molding, and SI engineers discuss impedance, crosstalk, and insertion loss.

Additionally, this is not considering the business aspect because engineers typically do not give too much thought to costs. As we can see, designing high-speed connectors involves many different disciplines and is more complicated than just joining metal and plastic.

Additional Ansys Software Tips & Tricks Resources

-

- Analyzing normal and Tangential Elastic Foundations in Mechanical

- Why Meshing is Crucial for FEA Fluid Simulations Prior to Prototyping

- For support on Contained Fluid FEA Modeling with HSFLD242 Elements

- For Exporting a Deformed Geometry Shape Post-Analysis in Mechanical

- Moreover, for guidance Multi-Step Analyses in Mechanical

- For Retrieving Beam Reaction Force in a Random Vibration Analysis

- Deploying Ansys Macro Programming vis *USE Command in Mechanical

- For replicating Fatigue Models from Start to Finish in Mechanical

- In addition, setting up Acoustic Simulations of a Silencer

- For a step-by-step guide on 2D to 3D Submodeling in Mechanical

- For modeling Pipe16 Circumferential Stress in Mechanical

- For Support on performing ‘EKILL‘ in Workbench

- APDL Command Objects post-Spectral Analysis

- For Separating DB Database Files from RST Files

- Measuring Geometric Rotation in Mechanical WB

- Explicitly, CAD Geometry Deformation Plasticity

- Offsetting a Temperature Result to Degrees Absolute

- For general guidance on Ansys Post-Processing

- Finally, for basic Ansys Software Installation and License Manager Updates