As electric machines become smaller and faster, designers face growing challenges. Deliver machines that meet all your electrical, mechanical, and thermal design goals while significantly reducing time-to-market.

Electric machines have different requirements according to industry. For example, in the automotive industry, electrical machines commonly need to be:

- Compact, given the limited space available

- Lightweight and efficient, with increased driving range and extended battery life

- Quiet, for maximum passenger comfort

Intuitive Interface for Electric Machine Design

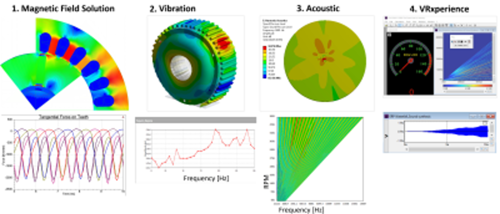

With multiple types of analyses required, designers need to seamlessly move from one analysis to another efficiently. And a problem that presents itself downstream may require that upstream analyses be revisited.

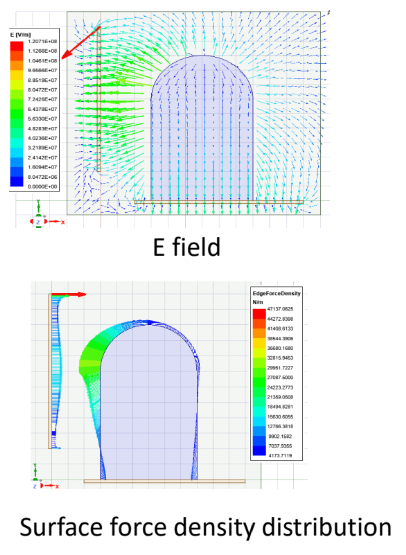

Optimizing Power Dividers and Directional Couplers

Passive components utilized mostly in the realm of radio technology include directional couplers, power dividers, power splitters, and, when employed in reverse, power combiners.

The signal can be used in another circuit because they connect a certain amount of electromagnetic energy to a port in a transmission line. The fact that directional couplers only couple power flowing in one direction is a crucial component. The isolated port receives power entering the output port, but the coupled port does not.

A hybrid coupler is a directional coupler created to distribute power equally between two ports. Two connected transmission lines placed close enough to one another to allow energy going from one to be coupled to the other form directional couplers.

Adjusting Machine Design based on Thermal Analysis Results

For instance, if the thermal analysis reveals an overheating issue, then perhaps the upstream electrical analyses needs to be adjusted and the process started again. Furthermore, once an acceptable design is completed, the design may not yet be optimal. It just means that the design is in the ballpark.

To assist electrical machine designers with their challenges, Ansys simulation tools can help streamline the design process. We recently hosted a one-hour webinar “Electric Machine Design in Ansys” that discusses how to analyze the initial electric machine design quickly in RMxprt.

We also demonstrated how to automatically create a Maxwell model for accurate and detailed analyses, and then use the user-friendly design toolkit to create an efficiency map.

We also covered system simulation, including electric drive circuit using Twin Builder, and electric machine multi-physics simulation for stress and thermal analyses using Maxwell and Ansys Mechanical™.

If you need assistance with your electrical motor design, our engineers can help. Please contact us at (800) 566-9190 or drop us a note on our contact page HERE to discuss your challenges.