Ansys Polyflow

Ansys Polyflow is a polymer processing simulation software used to reduce the cost of polymers, glass materials, metals, and cement processing.

Ansys Polyflow is a polymer processing simulation software used to reduce the cost of polymers, glass materials, metals, and cement processing.

Ansys Polyflow assists in making the most accurate decision decisions. With Polyflow, accelerate your design time while minimizing the demands of energy and raw materials for manufacturing processes. Design engineers are able to easily explore behaviors of different plastics and elastomers to ensure your product will be manufactured exactly the way you designed it.

Ansys Polyflow’s high-performance solvers provide the ability to solve nonlinear material deformations and also carries the capability to make the distinction between tools and materials when applying a mesh. This innovative capability aids in die design and allows you to accurately predict product performance. Engineers leverage Ansys Polyflow to reduce costly trial and error methods.

By optimizing your products before running full production within your manufacturing process, you reduce the number of prototypes required saving you both time and production costs.

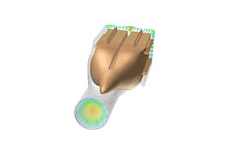

Packaging is necessary to preserve products from damage, but it also has environmental implications and adds to the cost of goods for suppliers. You can model the package manufacturing process by deploying a virtual prototyping using Ansys Polyflow. You or your R&D team can examine and test a design’s behavior and durability by combining this solution with Ansys Explicit Dynamics as well as Ansys Mechanical. To swiftly and cost-effectively design lighter packaging with better performance, you can take corrective action throughout the design process, throughout the manufacturing process, or both.

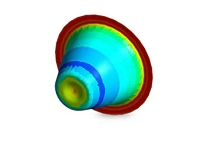

Ansys Polyflow allows you to virtually design, simulate, and test extrusion dies. Polyflow allows you to simulate the extrusion process to automatically perform die shape optimization. Using Polyflow allows you to evaluate numerous design options, design dies faster, investigate and eliminate flow related problems, and reduce costs for engineering and extrusion line time, reduced costs for die fabrication, and reduced costs for scrap materials.

Ansys Polyflow provides an extensive library of mathematical material models to accurately characterize material behaviors. The Ansys Polyflow material library allows you to understand behaviors of new plastics and elastomers for various applications such as extrusion, blow molding, fiber spinning, film casting, and thermoforming. Ansys Polyflow allows you to test new resins without physically producing the resin by comparing prototypes with different materials to evaluate the performance of existing and competitive materials. Polyflow allows you to reverse-engineer a resin to maximize product performance while maintaining sustainability efforts and minimizing costs.

Ansys Polyflow is able to simulate viscous heating to detect potential deterioration of polymer grades or unplanned rubber curing. In use cases such as glass forming which needs accurate modeling of high temperature processes, advanced nonlinear material properties, radiation prediction, and the Narayanaswamy model are required.

Ansys Polyflow provides a native fluid-structure interaction (FSI) to simulate the interactions of flowing materials and surrounding solids in a coupled approach. Polyflow is able to automatically refine a mesh resolution to improve the quality of your analysis when there are large deformations within the elastic zone. You can also seamlessly export your analysis results to Ansys Mechanical to perform a structural analysis and you can import the data within Ansys Explicit Dynamics tools to assess drop tests and top-loading deformations.

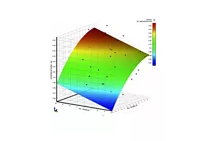

Ansys Polyflow allows you to evaluate multiple designs while optimizing flow and geometric parameters for your equipment designs and processes. You can select any scalar as an optimization variable such as rheological parameters, boundary conditions, as well as mesh displacements. You can also use the integrated optimization algorithm to make automatic adjustments to minimize or maximize a given objective based on your input parameters.

Ansys’ most powerful computational fluid dynamics tool, Fluent, includes well-validated physical modeling capabilities to deliver fast, accurate results across the widest range of CFD and multiphysics applications.

Ansys CFX is a high-performance computational fluid dynamics tool that delivers reliable and accurate solutions quickly for a wide range of applications, including leading capabilities for rotating machinery.

Ansys EnSight is the market leader for data visualization. Its post-processing tool includes models with more than hundreds of millions of cells, providing engineers with insights unavailable elsewhere.

Ansys Polyflow provides advanced fluid dynamics technology for companies in the polymer, glass, metals, and cement processing industries.

Ansys Chemkin-Pro is the gold standard for modeling and simulating complex gas phase and surface chemistry reactions for fast, accurate development of combustion systems.

Ansys TurboGrid complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Ansys Forte accurately simulates IC engine combustion performance with nearly any fuel, helping engineers rapidly design cleaner burning, high-efficiency, fuel-flexible engines.

Ansys Vista TF complements rotating machinery simulation by enabling engineers to quickly develop blade geometries that achieve desired performance objectives.

Ansys BladeModeler complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Mosaic Mesh, a Hexahedral Dominant Mesh Software accelerates the meshing process with a reduced face count, higher quality cells and efficient parallel scalability.

FENSAP-ICE is the premier in-flight icing simulation system. Its innovative, graphical environment provides intuitive file management and makes it easy to interact between simulation modules.

Fluent meshing provides automation to highly crafted meshing. Methods available cover the meshing spectrum of high-order linear elements to tetrahedral and polyhedral analysis.

To benefit from all the computational fluid dynamic solvers that Ansys offers, choose the CFD Enterprise toolkit. CFD Enterprise offers full versions of Ansys Fluent, AIM Pro, and CFX to help you optimize product performance with well-validated physical modeling capabilities that deliver quick, accurate results.

Engineers use Ansys CFX for the most accurate, robust, and rapid simulation for rotating machinery such as fans, pumps, compressors, and gas and hydraulic turbines. Companies in the glass, metals, polymer, and cement industries can choose Ansys Polyflow for advanced fluid dynamics technology.

Today’s experienced engineers need well-validated CFD results to analyze products quickly and thoroughly. With full versions of Ansys Fluent, CFX, and SpaceClaim included, CFD Premium provides accurate, quick, and robust results.

Engineers can simulate IC engine combustion performance with Ansys Forte. Simulate with nearly any type of fuel to quickly design high-efficiency, clean-burning engines that are fuel flexible. To ensure speed and safety for in-flight icing certification, Ansys FENSAP-ICE provides accurate, rapid aircraft icing assessments, along with other comprehensive analysis in the aerospace industry.